Page 10

ENGLISH

Jandy

®

Pro Series, Hi-E2

®

and Hi-E2R Gas-Fired Heater

|

Installation & Operation Manual

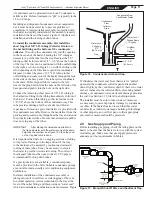

Figure 10. Installation of insect screens.

Install special

insect screen

at end of pipe

inside coupling

or elbow. Cut

to size as nec-

essary.

Combustion

Air Pipe

Elbow

Vent

Exhaust

Pipe

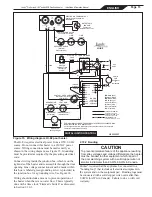

Figure 11. Condensate drainage components.

To

Disposal

Vent

Drain

Collector

Drain

Trap/

Neutralizer

Blower

Drain

As shown in Figures 8 and 9, the combustion air intake

and the vent outlet must be installed no closer together

than 18" (45.7cm) and no farther apart than 60" (1.5m).

The combustion air inlet opening must face downward

to prevent entry of rain or snow. The vent outlet must

discharge away from the combustion air inlet - normally

in a horizontal direction when on a wall and vertically

upward when on a roof. Both should terminate at least

12" (30.5cm) above the snow accumulation level. In

locations with freezing climate, extension of the vent pipe

outside of the building should be minimized. The insect

screens provided with the heater must be installed at the

combustion air and vent pipe openings as shown in Figure

10. Insect screens are sized to fit the inside of a 5" PVC

pipe fitting. Trim them as necessary for smaller pipe sizes.

Connect the vent pipe to the heater vent collar with an air-

tight corrosion-resistant clamp. The connection must not

allow leakage of combustion products into the space but

should be removable for service. See Figure 7.

Connect the combustion air pipe to collar of the air filter

box. For this

combustion air pipe only

, sheet metal pipe is

most convenient and can be screwed directly to the collar.

Seal the joint with silicone sealer or similar mastic material.

Install vent piping with a continuous rise of at least 1/4"

per foot (20 mm per meter) away from the heater. This will

assure that any condensate forming in the vent pipe will

flow back to the heater where it can be disposed of properly.

Support vent piping with suitable hangers so its weight

does not bear on the heater or building penetration and

so that piping joints are not strained. Support horizontal

runs at intervals no greater than 6 feet (1.82 meters), and

closer if necessary to avoid sagging. Sagging can trap

condensate water and block the vent.

Both combustion air and vent piping joints must be sealed.

Metal combustion air pipe joints should be fastened with

screws and sealed with permanent sealer or tape. Plastic

vent pipe joints must be made with solvent cement listed

for such use. Joints in 29-4C

®

stainless steel pipe must

be sealed in accordance with its listing. Connection of

combustion air and vent piping to the heater should be

serviceable — i.e. removable for heater service.

2.7.3.5 Room Ventilation

The room a Hi-E

2

is installed in must be provided with

adequate ventilation. Like other gas-fired appliances, the

Hi-E

2

releases heat to its environment, and a room with no

ventilation may become too warm.

In one-pipe installations, the normal (code-required)

provisions for combustion air also assure reasonable

ventilation of the room. If a two-pipe system is installed,

ventilation must be provided by other means, such as

through grilles or openings or with a small fan.

2.7.3.6 Inspection and Replacement of

Existing Vent System with New

Components

If the Hi-E

2

is being installed to replace an existing pool

heater, it is recommended that a new appropriate venting

system be installed with the new heater. However, if

an existing venting system must be used, be sure to

carefully inspect the venting system to ensure that it is

in good condition and continues to be appropriate for the

Hi-E

2

heater. Replace any parts that are not in good and

serviceable condition with new parts before completing

the pool heater installation.

2.8 Condensate Disposal

In a high-efficiency combustion process, combustion

product gases are cooled so much that liquid water is

condensed. Flow of this “condensate” can be quite high.

When pool water is very cold, as much as 2 or 3 gallons

Содержание HI-E2

Страница 2: ......

Страница 37: ...Page 37 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...

Страница 38: ...Page 38 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...

Страница 39: ...Page 39 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...