Page 11

ENGLISH

Jandy

®

Pro Series, Hi-E2

®

and Hi-E2R Gas-Fired Heater

|

Installation & Operation Manual

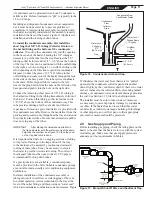

Figure 12. Condensate drain and trap.

Trap

Overfl ow

To

Disposal

Water Level

Pushed Down

Slightly

Water Level

Pulled Up

2"-3"

(50-75 mm)

Condensate

From

Collector

Drain

Condensate From

Vent/Blower Drains

1/4" - 3/8"

(6-10 mm)

Figure 13. Manual Shut-off Valve and Sediment Trap.

of condensate can be produced in an hour. Condensate is

mildly acidic. Before treatment, its “pH” is typically in the

3.5 to 6.0 range.

Handling and disposal of condensate is not complicated,

but it must be done correctly to prevent problems or

complaints. A trap/neutralizer assembly is provided with

the heater to simplify installation. This assembly is easily

installed in the base of the heater. Figure 11 illustrates its

installation and the routing of drain tubes.

To install the condensate assembly, fi rst install the

short length of 5/8" I.D. tubing (Collector Drain) on

the barbed fi tting on the bottom of the condensate

collector.

Then drop the condensate tray into the opening

in the base pan of the heater, bending the 5/8" tubing as

necessary to get the tube into the tray. Readjust the 5/8"

tubing so that its lower end is 1/4" - 3/8" above the bottom

of the tray. The tray can be positioned with the outlet fi tting

to the right, as shown in Figure 11, or with the fi tting to the

left, depending on the direction required for condensate

disposal. Connect the piece of 1/2" I.D. tubing to this

outlet fi tting and route it out of the heater through the hole

in the side of the base panel. This tube carries condensate

to the drain. If this disposal tube is routed to the left,

remove the plug button from the hole on the left side of the

base panel and push it into the hole on the right side.

Connect the remaining short piece of 3/8" I.D. tubing to

the barbed tee fi tting in the tubing immediately in front of

the blower. Position this tubing so that its bottom end is

1/4"-3/8" above the bottom of the condensate tray. This

tube provides drainage for the vent duct and blower.

A package of limestone gravel neutralizer is provided with

the condensate assembly. Remove the neutralizer from the

packing and spread evenly throughout the tray and around

the properly placed tubes. Be sure that a limestone pebble

does not plug any of the tubes.

IMPORTANT

After placing the limestone neutralizer in

the tray add water until the water level is at the same

height as the overflow, see figure 12. Place the cover

on the tray when this is done.

It is important that there be no sagging sections of tubing

to trap water. Drainage to the trap and out of the trap

to the drain must be assured by continuous downward

routing of these tubes. It may be necessary to elevate

the heater to provide downward routing. The outlet of

the disposal tube must be open to the air. PVC pipe is

recommended for long drain tubes.

If a gravity drain is not available, a condensate pump

must be provided in the fi eld. Suitable condensate pumps

are available commercially at air conditioning equipment

distributors.

Incorrect installation of the condensate assembly or

tubing can result in overfl ow or waterlogging of the vent.

In normal operation, water accumulates in the tray at the

level of the outlet fi tting, and this provides a “water seal”

which accommodates combustion system pressures. Figure

12 illustrates the water seal. Note that water is “pulled”

up toward the condensate collector pan and is pushed

down slightly by the vent/blower drain. If there is no water

seal, air rushes into the collector drain, preventing normal

drainage of condensate water, until vent drainage provides

the seal. See Section 2.12, Start-Up and Adjustment.

The installer must be sure to take whatever measures

are necessary to prevent property damage by condensate

overfl ow. If the heater location is such that this water

can directly or indirectly damage a building, furnishings

or other property, an overfl ow pan or other appropriate

preventative measure should be provided.

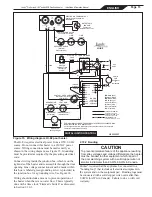

2.9 Gas Supply and Piping

Before installing gas piping, check the rating plate on the

heater to be sure that the heater is for use with the correct

(available) gas. Make sure that gas supply pressure is

adequate per the requirements in Table 4.

PIPE

NIPPLE

SEDIMENT TRAP

3 in

(

(

Содержание HI-E2

Страница 2: ......

Страница 37: ...Page 37 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...

Страница 38: ...Page 38 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...

Страница 39: ...Page 39 ENGLISH Jandy Pro Series Hi E2 and Hi E2R Gas Fired Heater Installation Operation Manual NOTES...