8

DC Input Channels

Two discrete voltage signals, 48-250 VDC. The “Aux A”

input is used to initiate the trip time log, the mechanism

time log, the arc duration time log, and the cumulative

I

2

T or I T duty log. The “Aux B” input is used to stop the

mechanism time log.

A continuous interrogation process detects Aux input logic

failure when both inputs are asserted or de-asserted at

the same time for longer than 3 seconds. This conflicting

input would indicate a serious problem with the circuit, DC

power has been lost, a wire is broken, etc. This condition

causes an “A-B Logic” alarm.

EVENT TRIGGERING

•

TRIP TIME

(opening time log) – (Available in

INPUT MODEs 2 & 4 only.) The start is triggered by

a positive assertion (rising edge) to the Aux A input.

The stop is triggered by the de-assertion (falling

edge) of the Aux A input, with the actual buffer stop

time adjusted by the software setting

A INPUT

DELAY

, which accounts for the time difference

between the Aux A de-assertion and the actual

parting of the main contacts.

•

ARC TIME

(arc duration log) – maximum duration

is 10 cycles per trip operation; the start time is

indexed by an assertion of the Aux A input, with the

actual buffer start time adjusted by the software

setting

A INPUT DELAY

, which accounts for

the time difference between the Aux A assertion

and the actual parting of the main contacts. A

proprietary algorithm that detects the end of arc

current in all three phases triggers the stop. See

Figure 6.

•

CLEARING TIME

(interrupting time log) –

(Available in INPUT MODEs 2 & 4 only.) The start

is triggered by the assertion (rising edge) of the Aux

A input. A proprietary algorithm that detects the end

of arc current in all three phases triggers the stop.

•

TRAVEL TIME

(mechanism time log) – (Available

in INPUT MODEs 1 & 4 only.) maximum duration is

10 cycles per trip operation; the start is triggered by

a change in state of the Aux A input. An assertion to

the Aux B input triggers the stop.

•

CLOSING TIME

(mechanism time log) – (Available

in INPUT MODE 1 only.) maximum duration is 10

cycles per trip operation; the start is triggered by

an assertion to the Aux B input. An assertion to the

Aux A input triggers the stop.

•

MAIN CONTACT ARCING DUTY LIFE

(phase

segregated I

2

T or I T per trip operation and phase

cumulative

I

2

T or I T data log); A mathematically

calculated value representative of the destructive

arc energy.

FIELD OUTPUTS

Visual Display

On-board LEDs will illuminate and latch when reaching an

alarm setpoint or detecting a failure mode. These may be

reset by software command.

The circuit breaker OPEN / CLOSED status is also

shown by green and red LEDs on the

OPTI

mizer

2

. This

OPEN / CLOSED status indicator should only be used as a

secondary indication and to verify correct programming of

A INPUT POLARITY

and

B INPUT POLARITY

assertion

states.

An LED bar graph alternates every 10 seconds between

indicating the remaining contact life and the SF

6

gas level.

In both cases, the condition of the worst phase is displayed.

When more than one LED is lit, the contact life is being

displayed. When a single LED is lit, the SF

6

level is being

displayed.

The scale is -50% to +100% for contact life. The scale for SF

6

gas level is based upon the programmed SF

6

Fill (density

or pressure), the Low Gas Warning Limit and the low Gas

Alarm Limit.

When displaying remaining contact life, the green zone is

scaled from 100% remaining life to the Warning Limit. The

yellow zone is scaled from the Warning Limit to the Danger

Limit (0% life). The red zone is scaled from the Danger Limit

to 50% below the Limit.

When displaying SF

6

gas level, the green zone is scaled from

the Fill (density or pressure) value to the Low Gas Warning

Limit. The yellow zone is scaled from the Low Gas Warning

Limit to the Low Gas Alarm Limit. The red zone is scaled from

the Low Gas Alarm Limit to zero (pressure or density).

When the display is in the green zone, the LED(s) will be

lit continuously. When the display is in the yellow zone, the

LED(s) will flash slowly to indicate an approaching alarm

condition. When the display is in the red zone, the LED(s) will

flash rapidly to indicate an alarm condition exists. A slowly

flashing green heartbeat LED indicates that the

OPTI

mizer²

system is functioning normally.

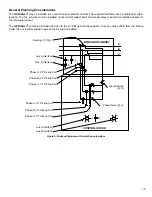

Relay Contacts

Two Form C relays and one Form A relay are provided

for alarms. The dry contacts are rated for 3A at 250 VAC

or 1 / 2A at 125VDC. These contacts are not intended

for breaking DC inductive loads. (For Alarm / relay

assignments, see Figure 8):

• The “RED” relay asserts when a Restrike or excess arc

duration is detected, or when the Contact Life Danger

limit is reached.

• The “YELLOW” relay asserts when a failed CT pickup

coil is detected, the Contact Life Warning limit is

reached, the Operations Count limit is reached, the

open or close mechanism time limit is reached, the Trip

Time limit is reached, the Clearing Time limit is reached,

the No Operations time limit is reached, or an A-B Logic

Alarm condition occurs.

• The SF

6

relay asserts when a Low Gas Alarm limit or

Trend Alarm limit is reached or if there is a malfunction

of the SF

6

sensor.