7

1 INTRODUCTION

1.1 Overview

The

OPTI

mizer

2

is an On-Line Circuit Breaker

Performance and SF

6

Gas Density Monitor that is used

for implementing predictive maintenance, maintenance

deferral, just-in-time (JIT) maintenance and environmental

protection. This intelligent electronic device (IED) monitors

the condition of the main contacts, mechanism and

dielectric; and logs the following information during CB

operation:

• Trip Time (mS) (also known as Opening Time)

• Arc duration (mS) (phase segregated)

• Clearing Time (mS) (also known as Interrupting Time)

• Cumulative I

2

x T or I x T on the main contacts (phase-

segregated) from arcing

• Restrike Occurrence (phase segregated)

• Mechanism opening travel time (mS)

• Mechanism closing travel time (mS)

• Operation Counts

The

OPTI

mizer

2

continuously monitors SF

6

(Sulfur

hexafluoride) gas density and temperature, and then

calculates gas pressure, density and pressure trend rates

and changes in mass. The present density, pressure,

mass, density and pressure trend rates, and temperature

are recorded in the history log at regular intervals. There

are alarms for low density and high density or pressure

trend rate.

In addition to alarming of anomalies by LEDs and contact

alarms, digital information is available for retrieval through

a DNP3.0 network or a web browser. The ability to provide

historical data, in addition to alarming at setpoints, makes

the

OPTI

mizer

2

ideal for reliability centered maintenance

(RCM) programs.

The

OPTI

mizer

2

has passed rigorous standards for

survivability in the electric utility substation environment. It

may be mounted directly in the circuit breaker cabinet, or

in the control house.

A minimal interface to the breaker control and secondary

current circuits is used, employing snap-on CT pickup coils

and two parallel wiring connections. This minimal interface

to the power circuit breaker makes the

OPTI

mizer

2

ideal

for both retrofit and new applications. One, two or three

SF

6

gas density sensors may be used.

The

OPTI

mizer

2

is specifically designed for use on gas

(SF

6

) circuit breakers, but can be used on oil and vacuum

breakers.

The wear models used in the

OPTI

mizer

2

are valid for any

voltage class and correspond to ANSI / IEEE C37.06-1989.

1.2 Operation Overview

CONDITION and WEAR LOGGING

• SF

6

Density (g / L), Pressure (PSIG, BAR, Kilopascals)

Mass (Pounds, Kilograms)

• SF

6

Trend Rate (units / day) Mass Loss (Pounds,

Kilograms, Pounds CO2, Metric Tonnes CO2)

• Trip Time (mS)

• Duration of the arcs (by phase) during tripping (mS)

• Clearing Time (mS)

• Cumulative I

2

x T or I x T on the contacts (phase

segregated) from the arcs during tripping

• Restrike Occurrence (by phase)

• Mechanism opening travel time (mS)

• Mechanism closing travel time (mS)

• Operation Counts (Time and Date Stamping is provided

for each trip operation.)

Alarm set-points may be entered against these items.

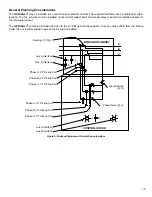

SENSING INPUTS

AC Current Input Channels

Three signals (one per phase) from split-core CT pickup

coils placed around the secondary of each circuit breaker

primary phase CT. The signal is proportional to 0-(Max) A

in the primary CT’s secondary circuit (where “Max”= 20,

30, 50, 100,160, 250, 400 or 800 Amps depending upon

the CT range chosen).

System frequency may be at 50 or 60 Hz. These signals

are used to record the arc duration and cumulative

I

2

x T

or

I x T

contact duty.

I

2

x T

or

I x T

calculations are accurate in

the presence of DC offset and sinusoidal harmonics up to

the 16th.

Split-Core CTs

The

OPTI

mizer

2

is designed to be used with

INCON

Split-Core pickup coils only

. Models CT-20, CT-30,

CT-50, CT-100, CT-160, CT-250, CT-400 and CT-800

are custom designed for the accuracy required by the

OPTI

mizer

2

. Range is 1.4-20A, 2.1-30A, 3.5-50A, 7.0-

100A, 11.2-160A, 17.5-250A, 28.0-400A and 56.0-800A

respectively. Three CT’s (one per phase) are provided in a

CT kit. These split-core CT pickup coils snap-on for easy,

non-intrusive installation to the circuit breaker secondary

current circuits. Burden is 0.05VA @ 5 amp.

SF

6

Input Channels

Two types of SF

6

gas density sensors may be used:

2-wire 4-20mA “analog” or INCON Model DSSP “digital”

type sensor. This input is user-configurable for up to

three sensors. For analog sensors, the density units

(grams / liter) are scalable over all or a portion of the

4-20mA signal range. Sensor power of 20VDC is provided

for each channel. SF

6

gas temperature can also be

measured if the “digital” sensor is used.