51

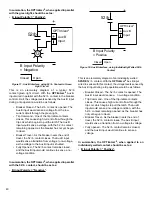

4.5 ACTIONS

An “Action” is taken in response to an alarm or

maintenance activity. Actions include clearing active

alarms; resetting data; resetting the operations counter;

pre-setting the remaining contact life percentage and

presetting the operation number. The

OPTI

mizer

2

allows

these things to be done from the “ACTION” tab of the user

interface (see Figure 10).

Preset Remaining Contact Life

The ability to preset the remaining contact life as a

percentage

of the Danger Limit for each phase allows the

OPTI

mizer

2

to account for any interrupting duty wear that

has occurred prior to installation. This issue may be divided

into two general categories:

• New breakers, or breakers that have been

recently refurbished, have essentially 100 percent

life remaining on one or more of the contacts.

Refurbished is defined here as replaced contacts, oil

and grids (baffles) in OCBs, and replaced contacts

and gas cleaning in SF

6

breakers, or contact and

baffle replacement in magblast air breakers.

• Existing breakers that have not had recent

maintenance (refurbishment)

There are two processes for estimating the percentage of

remaining contact life for existing breakers that have not

been recently maintained:

• Experience based on field engineers / technicians

who can evaluate the condition of contacts and rate

a percent of life lost, or percent of life remaining.

• Calculation from trip duty records from

Oscillographs, relays with Oscillographic capabilities,

relay target logs.

Experience Method of presetting Remaining Contact

Life per phase

A breaker may have been recently inspected by a field

engineer / technician whose expert knowledge of breaker

wear characteristics may allow declaration of a percent of

life remaining on contacts.

Calculation Method of presetting Remaining Contact

Life

In the calculation method, an attempt is made to

quantify the cumulative currents interrupted since the

last refurbishing of each phase of the breaker. This

quantification would include the summation of fault

operations and load breaks. (No-load breaks would be of

no consequence to the wear duty of the breaker.)

The general method is to add the total I² x T (or I x T) from

all fault operations to the total I² x T (or I x T) from all load

breaks for each phase. The equation used is similar to the

one used to derive the Danger Limit value, except that the

variables represent individual operations.

Use the equation WN = IN² T to determine Duty Wear for

each operation, where “W” is the Duty Wear, “N” is the

operation number, IN is the current interrupted for that

operation (squared if using the I² x T mode), and T is the

arc duration time of the breaker. Determining the time (T)

is discussed in the Danger Limit calculation, addressed

earlier in this section.

The summation of all interrupting duty (WN’s) for a

particular phase is used to arrive at a final accumulated

Duty Wear value for that phase. Divide this calculated Duty

Wear by the Danger Limit to get the accumulated Duty

Wear percentage. Subtract this percentage value from

100 to get the Remaining Contact Life percentage. This

percentage value is programmed as the Preset Remaining

Contact Life for this phase.

It may be difficult to obtain exact interrupted amps for each

and every operation. In these cases, some assumptions

must be made to arrive at an estimated setting. Possible

information sources may be from protective relay targets.

By examining the settings that relate to the targets,

estimates of the fault current may be obtained.

Lacking precise targets, by separating the operations

into fault operations and load break operations, some

assumptions can be made. One assumption may be

that load breaks equal ½ the maximum load the breaker

is subjected to, and fault operations are some factor of

expected short circuit ground current, or phase-to-phase

current.

As the great majority of fault incidences are phase-to-

ground, some factor relating to the expected ground short

circuit current can be made. The factors applied would

depend on knowledge of the relative fault currents that

have been recorded on the line to the short circuit ground

fault current assuming zero ground fault impedance.

System Protection and Operations personnel are helpful

sources for obtaining data for estimating the accumulated

Duty Wear if hard data is not available.