AR2 Conversion from RT•RTE

64

17730-241

AR2

™

40K • 46K

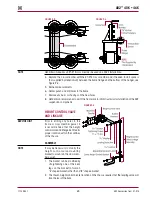

LONgITudINAL ANd TRANSVERSE TORquE ROdS

Refer to Preventive Maintenance section in this publication for complete longitudinal and trans-

verse torque rod inspection .

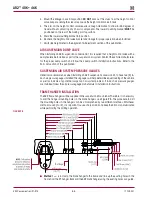

VEHICLE pREpARATION ANd SuSpENSION REMOVAL

dISASSEMBLY

1 . Chock the front wheels .

2 . Lift and support the frame .

3 . Lift and support the axles .

4 . Remove the tires .

SERVICE HINT

It is recommended that the suspension is at full rebound before installing the jack stands . This will

provide maximum clearance for removal and installation of suspension components .

SERVICE HINT

If the is equipped with a fifth wheel, to ease in AR2 installation it may be necessary to remove the

fifth wheel and re-install after AR2 suspension installation is completed .

5 . Mark the centerline of the old suspension on both sides of the frame .

6 . Disconnect and remove the old suspension . Leave the walking beams installed, unless being

re-bushed .

pREpARATION ANd INSpECTION OF SuSpENSION

1 . Clean the frame rail from rust and debris .

2 . Inspect the frame rail for any cracks or damage . Repair or replace as necessary .

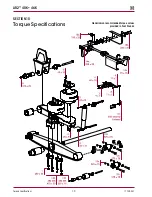

3 . Reference the schematic and lay out holes on the frame . Typically all holes are referenced

from the centerline of the front hanger, see Figure 9-1. If equipped with a non RT•RTE suspen

-

sions, the holes will be referenced from the centerline of the cross member .

NOTE

Prior to drilling any holes in the frame or cross member gusset it is recommended that the height

control valve and linkage be fitted for proper location within the confines of the chassis .

FIguRE 9‑1