Component Replacement

52

17730-241

AR2

™

40K • 46K

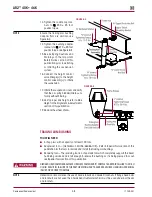

FIguRE 8‑22

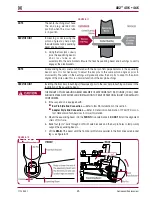

2 . Install Hendrickson Part No . 66086-103 (OTC 1757) end bushing installation tool (refer to

Special Tools section of this publication) on the new end bushing as shown in Figure 8-22 .

Tighten the through bolt until the two (2) halves of the tool touch . The installation tool com-

presses the rubber between the inner and outer metal of the bushing to allow press force to

be transmitted only to the outer metal of the bushing .

3 . Lubricate the equalizing beam end hub inside diameter AND the bar pin end bushing’s

outer metal with a heavy layer of NLGI #2 – EP (Extreme Pressure) lithium base grease, see

Figure 8-22 .

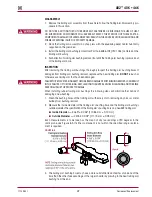

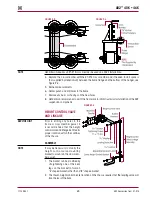

4 . Position the equalizing beam end bushing and installation tool on the end hub . Verify the bolt

holes in the end bushing are in line with the beam axis, see Figure 8-23 .

NOTE

The end bushing must be square with the equalizing beam end hub before pressing the end bush-

ing into the equalizing beam . End bushings pressed in at an angle will damage the end bushing

and the equalizing beam .

FIguRE 8‑23

5 . Verify the end bushing’s outer metal is square with the end hub . Damage to the equalizing

beam and the end bushing will result if the bushings are pressed in at an angle .

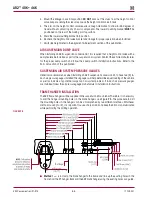

CARE MUST BE TAKEN DURING THE INSTALLATION OF THE BUSHING . DO NOT PUSH ON THE INNER

METAL OF THE BUSHING, DOING SO WILL CAUSE DAMAGE TO THE BUSHING AND VOID WARRANTY .

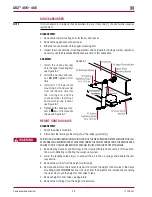

FIguRE 8‑24

6 . Install the end bushing into the end hub by

pressing on the installation tool until the

installation tool contacts the end hub . This

will center the bushing in the end hub, see

Figure 8-24 .

7 . Install the equalizing beam onto vehicle,

refer to the Equalizing Beam Assembly procedure in this section .