Component Replacement

54

17730-241

AR2

™

40K • 46K

FIguRE 8‑27

FIguRE 28

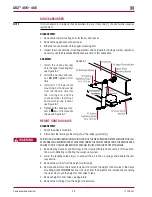

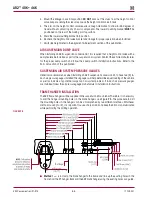

10 . The beam end adapters have two chisel recesses located in their flanges as shown in

Figure 8-28 .

11 . Locate the recess for the chisel, rotate the adapter if necessary . Place the air hammer / chisel

in the recess to rotate the adapter collar .

12 . If the beam end adapter does not turn, use a hammer to rap the outside of the axle bracket

legs around the adapter area and repeat air hammer chisel procedure until removed .

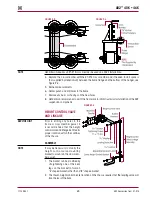

13 . Remove the beam end adapter from the other equalizing beam ends .

14 . Slowly lower the floor jacks and remove / pry the equalizing beams from the axle brackets .

15 . Remove the end bushing adapter tube (if equipped), see Figure 8-27 .

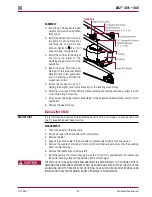

16 . Remove the floor jacks from under the equalizing beams .

17 . Position the equalizing beam in the shop press and align the end bushing removal /

replacement adapter tool with the

tapered end down

on top of the rubber end bushing,

see Figure 8-29 .

FIguRE 8‑29

CHECK TO ENSURE PROPER ALIGNMENT OF TOOLING

ADAPTERS WITH EQUALIZING BEAM COMPONENTS

BEFORE APPLYING FULL HYDRAULIC PRESSURE WITH

A SHOP PRESS .

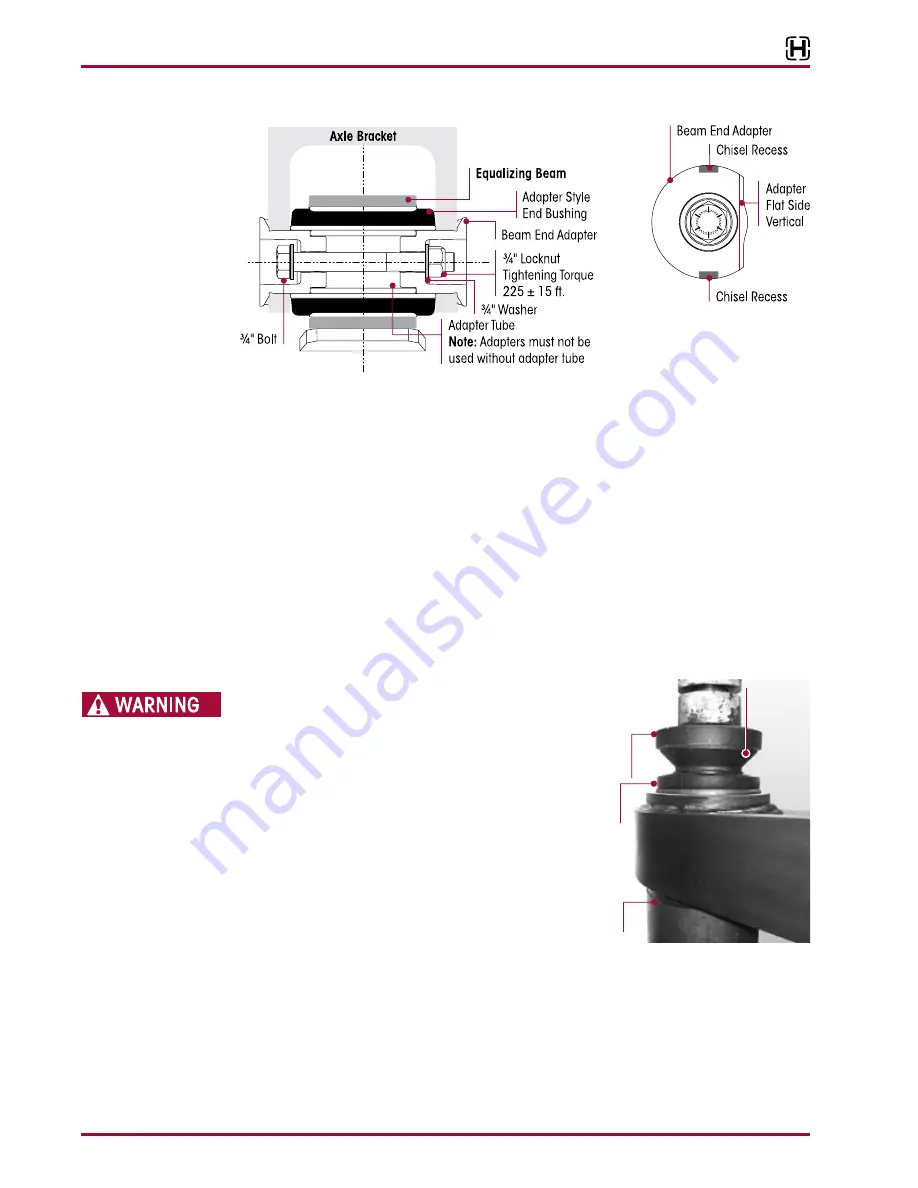

18 . Apply hydraulic force and remove the

old bushing .

19 . Inspect the axle bracket legs per the Beam End

Axle Brackets, Physical Inspection for Adapter

Style bushings in the Preventive Maintenance

section of this publication .

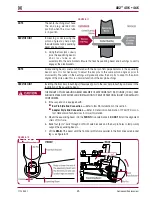

INSTALLATION

1 . Clean the equalizing beam bushing bore with a

cylinder ball hone or emery paper of any debris .

2 . Lubricate the equalizing beam bore and the equalizing beam center bushing outer metal

sleeve with an NLGI#2 – EP (Extreme Pressure) grease, see Figure 8-30 .

3 . Position the end bushing removal / replacement adapter with the

tapered end up

onto the

clamp, see Figure 8-31 .

4 . Use a wrench to tighten the installing clamp tool on the rubber bushing and the end bushing

replacement adapter as shown in Figure 8-31 .

End Bushing

Replacement

Adapter

Receiver

Equalizing Beam

End

Bushing

Tapered

End Down