17730-241

23

Preventive Maintenance

AR2

™

40K • 46K

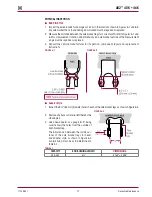

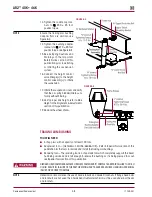

FIguRE 6‑12

Both types of rods may have torque

rod bushings designated “straddle

mount” or “tapered stud” as shown

in Figure 6-12 . Both types can be

replaced by pressing out the worn

bushing and installing a new genu-

ine Hendrickson bushing . For proper

replacement instructions, refer to the

Component Replacement section in

this publication .

It is important to check the torque rod fasteners for proper torque values, refer to the Torque

Specifications section in this publication .

NOTE

Hendrickson recommends Grade 8 bolts, hardened flat washer and Grade C locknuts be used for

all straddle mount torque rods .

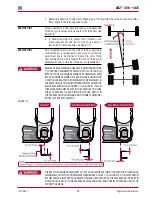

SAddLE CONNECTION

Visually inspect for any signs of movement or looseness . Ensure:

■

Each saddle is centered on each equalizing beam center bushing

■

The center bushing inner metal is full seated to the saddle

■

The saddle cap fasteners are tightened to the proper torque, see Figure 6-13 . Saddle cap

fasteners have a phosphate oil coating

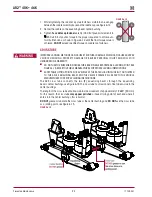

THE TRAILING ARM ASSEMBLIES ARE ATTACHED TO THE CENTER BUSHINGS OF EACH EQUALIZING BEAM

WITH TWO (2) SADDLE CAPS . EACH SADDLE CAP USES TWO (2) STUDS TO CLAMP THE CENTER BUSHING

INNER METAL TO THE SADDLE . THE SADDLE CAPS MUST BE INSTALLED AND TIGHTEN SO THAT THERE IS

AN EVEN GAP BETWEEN THE SADDLE CAPS AND THE BASE OF THE TRAILING ARM ASSEMBLY AS SHOWN

IN FIGURE 6-13 . IF THEY ARE NOT INSTALLED PROPERLY, THE TRAILING ARM ASSEMBLIES COULD BECOME

DEFORMED, RESULTING IN BENT BOLTS OR ASSEMBLY DAMAGED .

LOOSE OR OVER TORQUED FASTENERS CAN CAUSE COMPONENT DAMAGE, ADVERSE VEHICLE

HANDLING, PROPERTY DAMAGE, OR SEVERE PERSONAL INjURY . MAINTAIN CORRECT TORQUE VALUES

AT ALL TIMES . CHECK TORQUE VALUES ON A REGULAR INSPECTION INTERVAL .

FIguRE 6‑13