Important Safety Notice

6

17730-241

AR2

™

40K • 46K

■

SAFETY pRECAuTIONS

FASTENERS

DISCARD USED FASTENERS . ALWAYS USE NEW FASTENERS TO COMPLETE A REPAIR . FAILURE TO DO

SO COULD RESULT IN FAILURE OF THE PART, OR MATING COMPONENTS, ADVERSE VEHICLE HANDLING,

PERSONAL INjURY, OR PROPERTY DAMAGE .

LOOSE OR OVER TORQUED FASTENERS CAN CAUSE COMPONENT DAMAGE, ADVERSE VEHICLE

HANDLING, PROPERTY DAMAGE, OR SEVERE PERSONAL INjURY . MAINTAIN CORRECT TORQUE VALUE

AT ALL TIMES . CHECK TORQUE VALUES ON A REGULAR BASIS AS SPECIFIED, USING A REGULARLY

CALIBRATED TORQUE WRENCH . TORQUE VALUES SPECIFIED IN THIS TECHNICAL PUBLICATION ARE FOR

HENDRICKSON SUPPLIED FASTENERS ONLY . IF NON HENDRICKSON FASTENERS ARE USED, FOLLOW

TORQUE SPECIFICATION LISTED IN THE VEHICLE MANUFACTURER’S SERVICE MANUAL .

BEAM ENd CONNECTION ANd SAddLE CAp FASTENERS

DO NOT ASSEMBLE BEAM END CONNECTION WITHOUT PROPER FASTENERS . HENDRICKSON

RECOMMENDS THE USE OF HENDRICKSON FASTENERS TO SUSTAIN PROPER CLAMP FORCE . FAILURE

TO DO SO CAN CAUSE ADVERSE VEHICLE HANDLING, PROPERTY DAMAGE OR PERSONAL INjURY .

ENSURE THAT BEAM END CONNECTION AND SADDLE CAP FASTENERS TORQUE VALUE ARE SUSTAINED

AS RECOMMENDED IN THE TORQUE REQUIREMENTS SECTION OF THIS PUBLICATION . FAILURE TO SO

CAN CAUSE ADVERSE VEHICLE HANDLING RESULTING IN PERSONAL INjURY OR PROPERTY DAMAGE .

IF BEAM END BUSHING MOVEMENT OR LOOSENESS IS NOTED IN THE EQUALIZING BEAM END HUB, DO

NOT OPERATE THE VEHICLE . REPLACE THE END BUSHINGS AND ALL CONNECTING PARTS . THE ABOVE

CONDITION CAN RESULT IN COSTLY REPAIR, DOWNTIME, POSSIBLE SEPARATION OF COMPONENTS,

ADVERSE VEHICLE HANDLING, PROPERTY DAMAGE, OR PERSONAL INjURY .

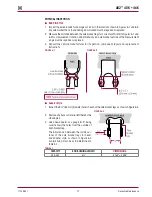

TRAILINg ARM ASSEMBLY CONNECTION

THE TRAILING ARM ASSEMBLIES ARE ATTACHED TO THE CENTER BUSHINGS OF EACH EQUALIZING BEAM

WITH TWO (2) SADDLE CAPS . EACH SADDLE CAP USES TWO (2) STUDS TO CLAMP THE CENTER BUSHING

INNER METAL TO THE SADDLE . THE SADDLE CAPS MUST BE INSTALLED AND TIGHTEN SO THAT THERE IS

AN EVEN GAP BETWEEN THE SADDLE CAPS AND THE BASE OF THE TRAILING ARM ASSEMBLY AS SHOWN

IN FIGURE 3-1 . IF THEY ARE NOT INSTALLED PROPERLY, THE TRAILING ARM ASSEMBLIES COULD BECOME

DEFORMED, RESULTING IN BENT BOLTS OR ASSEMBLY DAMAGED .

FIguRE 3‑1

LONgITudINAL / TRANSVERSE TORquE ROd

AR2 SUSPENSION INCORPORATES LONGITUDINAL AND TRANSVERSE TORQUE RODS FOR VEHICLE

STABILITY . IF THESE COMPONENTS ARE DISCONNECTED OR ARE NON-FUNCTIONAL, THE VEHICLE

SHOULD NOT BE OPERATED . FAILURE TO DO SO CAN RESULT IN ADVERSE VEHICLE HANDLING,

ADVERSE VEHICLE HANDLING, POSSIBLE TIRE CONTACT WITH THE FRAME, PREMATURE COMPONENT

DAMAGE, OR SEVERE PERSONAL INjURY .