17730-241

21

Preventive Maintenance

AR2

™

40K • 46K

BAR pIN ENd BuSHINg

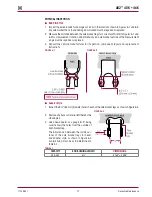

FIguRE 6‑9

An indication that the bar pin end bushing

requires replacement is when one or more of

the following conditions apply:

Visual inspection of:

■

Contact areas (the flat face areas where

bar pin contacts the axle bracket) on the

bar pin reveals signs of excessive wear

■

The bolt holes in the bar pin reveals signs

of elongation or wear, see Figure 6-9

Bar pin replacement is required, see Figure 6-9,

if the bar pin thickness measures less than:

■

with shims

— 1 .874" (47 .59 mm)

■

without shims

— 2 .252" (57 .2 mm)

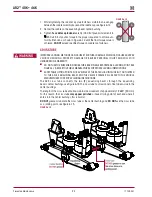

BAR PIN SHIMS

An indication that the bar pin shims require replacement is when one or more of the following

conditions apply:

■

Visual inspection of contact areas on the shim reveals signs of excessive wear

■

The thickness of any single leg on the shim, is less than the measurement shown in

Figure 6-10, replacement of bar pin shim is required

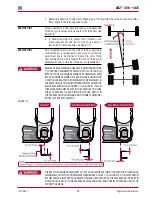

FIguRE 6‑10

Original

Thickness

of Shim Leg

Minimum

Thickness

Required

Part Number

1

⁄

8

" (3 .2 mm)

0 .123" (3 .1 mm)

50131-000

3

⁄

16

" (4 .8 mm)

0 .186" (4 .7 mm)

50130-000

¼" (6 .4 mm)

0 .248" (6 .3 mm)

50131-000

3

⁄

8

" (9 .5 mm)

0 .371" (9 .4 mm)

57026-000

RuBBER CENTER BuSHINg

An inspection of the center bushing is necessary when a vehicle is in the shop for major repair

work or every twelve months . Look for:

■

Any metal to metal contact

■

Worn, frayed, or distorted rubber in the center bushing

■

The bushing inner metal that is not centered in the bushing

■

Any equalizing beam to saddle contact