Alignment & Adjustments

30

17730-241

AR2

™

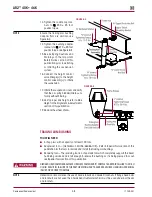

40K • 46K

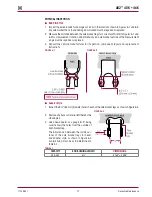

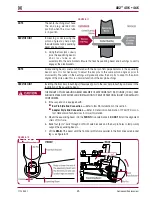

TO CHECK THE pINION ANgLE

1 . Use a work bay with a level floor .

2 . Relax the suspension by slowly moving the vehicle back and forth several times in a straight

line without using the brakes . This will slacken or loosen the suspension as the vehicle is posi-

tioned . End with all wheels positioned straight ahead . Roll to a stop without the brakes being

applied .

dO NOT

set the parking brake .

3 . Chock the front wheels of the vehicle .

4 . Verify vehicle is at the proper ride height (see Ride Height in this section) .

5 . Place a digital protractor on the axle housing as shown in Figure 7-4 .

6 . Check to see if the pinion angle is correct per the vehicle manufacturer’s specified range .

7 . If necessary, add / remove shims at the longitudinal torque rod connections as required to

achieve the proper pinion angle .

8 . When the pinion angle is correct tighten all fasteners to the proper torque specifications per

the vehicle manufacturer and recheck the pinion angles .

9 . Remove wheel chocks .

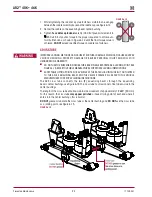

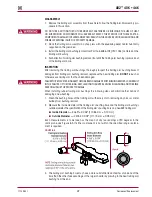

dRIVE AxLE ALIgNMENT

NOTE

Drive axle alignment with suspensions equipped with adapter style beam or non-shim style end

connections

ARE NOT

adjustable .

Computerized alignment equipment is the preferred method of measuring alignment . To calculate

the shim thickness required, the target offset must be converted to thrust angle, see alignment

equipment manufacturer for procedures . If, however, computerized axle alignment equipment is

not available refer to the following Inspection in this section .

Proper alignment is essential for maximum ride quality, performance, and tire service life . The fol-

lowing recommended alignment procedure as described below, should be performed if excessive

or irregular tire wear is observed .

NOTE

Proper vehicle alignment can only be achieved when all axles are aligned to the vehicle’s center-

line and the steering axle’s caster, camber and toe-in settings are within specifications .

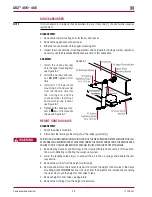

FIguRE 7‑5

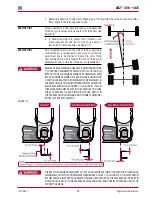

INSpECTION

1 . Use a work bay with a level, flat surface .

2 . Relax the suspension by slowly mov-

ing the vehicle back and forth several

times in a straight line . This will slacken

or loosen the suspension as the vehicle

is positioned . End with all wheels posi-

tioned straight ahead .

3 .

dO NOT

set the parking brake . Chock

the front wheels of the vehicle .

4 . Verify and maintain the air system at

full operating pressure .

5 . Verify all suspension components are

in good condition . Repair or replace

any worn or damaged suspension

components before proceeding with

the alignment process .