17730-241

55

Component Replacement

AR2

™

40K • 46K

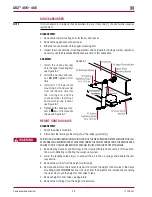

FIguRE 8‑30

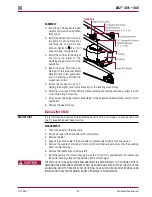

FIguRE 8‑31

CHECK TO ENSURE PROPER ALIGNMENT OF TOOLING

ADAPTERS WITH EQUALIZING BEAM COMPONENTS

BEFORE APPLYING FULL HYDRAULIC PRESSURE WITH

A SHOP PRESS .

5 . Apply hydraulic force and press the new bush-

ing into place . The bushing will be completely seated when the clamp makes contact with the

beam face .

6 . Using the floor jacks, slowly raise both equalizing beams and cross tube as an assembly

into the axle brackets . Ensure that each equalizing beam end bushing correctly engages

the axle bracket .

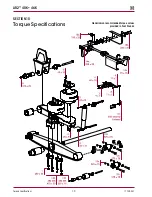

7 . Install one (1) adapter through the axle bracket leg at the wheel side, into the beam

end bushing .

8 . Install the other adapter through the axle bracket leg at the axle side, taking advantage of the cut-

off flange on the adapter to clear the axle .

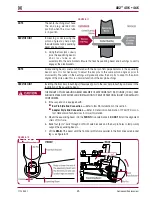

FIguRE 8‑32

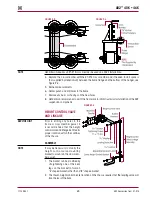

FIguRE 8‑33

9 . Rotate the adapters so that the adapter cut-off flats are vertical as shown in Figure 8-32 .

10 . Install the end shaft and slotted nuts .

11 . Place the axles in their normal operating positions before the slotted nuts are torqued to

specifications .

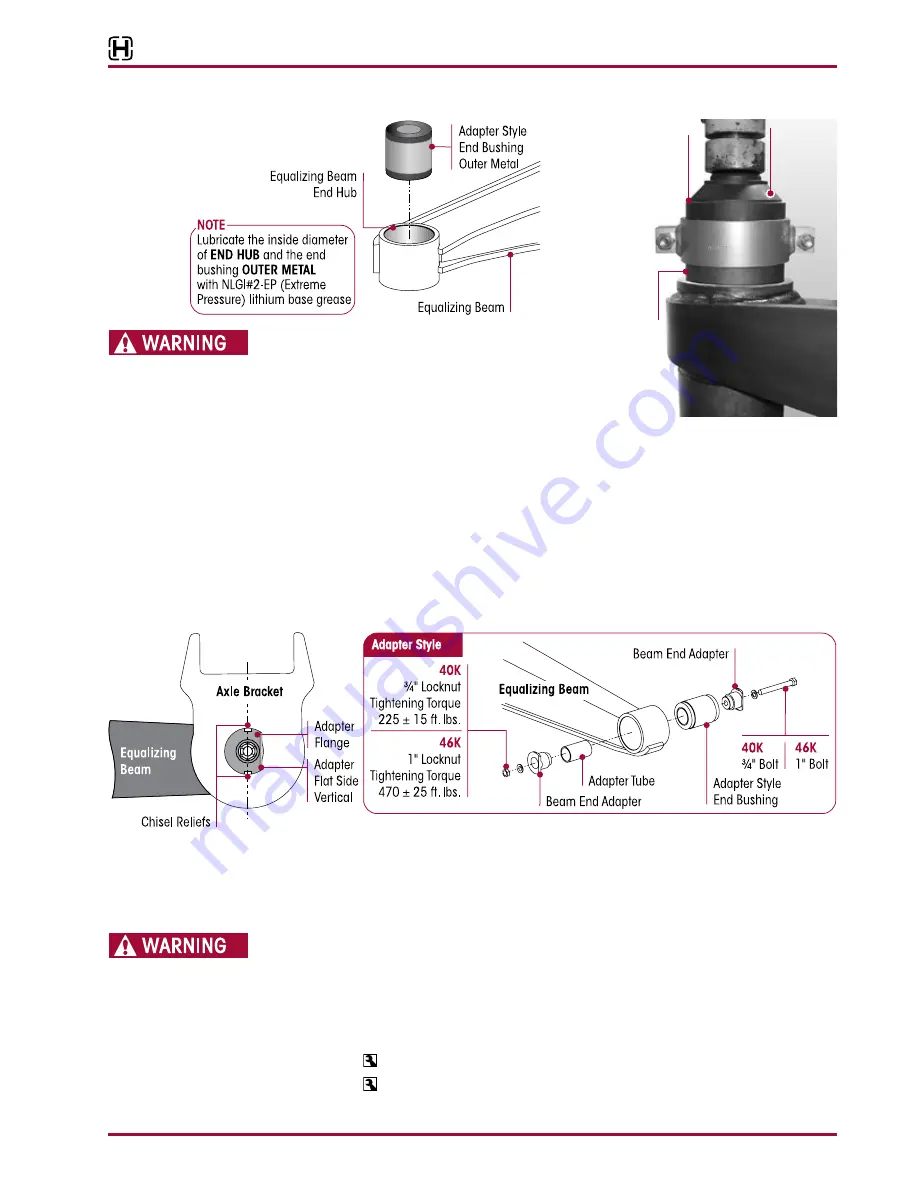

IF THE TIGHTENING TORQUES RECOMMENDED BELOW ARE NOT PROPERLY MAINTAINED, THE METAL

SURFACES OF THE AXLE BRACKET LEGS, HOLES, ADAPTERS AND RUBBER BUSHING INNER METALS CAN

EXPERIENCE EXCESSIVE WEAR AND / OR FAILURE . THIS CAN CAUSE SEPARATION OF COMPONENTS

AND ADVERSE VEHICLE HANDLING, PROPERTY DAMAGE OR PERSONAL INjURY .

12 . Tighten the locknuts until final torque value is achieved,

dO NOT ExCEEd

specified

torque value

.

■

40K

— 225 ± 15 foot pounds torque

■

46K

— 470 ± 25 foot pounds torque

13 . Remove the frame supports and lower the saddle onto the center bushings .

Adapter

Tool

Clamp

Equalizing Beam

Adapter Style

Rubber End

Bushing

Tapered

End Up