17730-241

53

Component Replacement

AR2

™

40K • 46K

AdApTER STYLE ENd BuSHINg

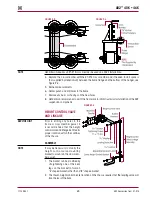

FIguRE 8‑25

YOu wILL NEEd

■

A shop press with a capacity of at least

100 tons

■

Air hammer / chisel / Bent chisel, see

Figure 8-25

■

Hendrickson Part No . 66086-102 (OTC Part

No . 1764), see Special Tools section of this

publication

REMOVAL

THE ADAPTER REMOVAL PROCESS CAN CAUSE DAMAGE . REUSE OF DAMAGED OR WORN ADAPTERS

COULD RESULT IN A COMPONENT FAILURE LEADING TO ADVERSE VEHICLE HANDLING AND POSSIBLE

PERSONAL INjURY .

SERVICE HINT

It is recommended that a penetrating oil be applied to all beam end connections prior to removal

to aide in disassembly .

1 . Chock the wheels of the steer axle .

2 . Raise and support the drive axles with safety stands .

3 . Remove the tires .

PRIOR TO REMOVING BOTH EQUALIZING BEAMS, SUPPORT THE PINION OF EACH DRIVE AXLE . FAILURE

TO DO SO CAN RESULT IN PERSONAL INjURY OR ALLOW THE AXLES TO SHIFT MAKING REASSEMBLY

MORE DIFFICULT .

4 . Support the pinion angle of the drive axles to prevent axle movement during service .

5 . Remove and discard the saddle cap fasteners from both inboard and outboard sides of the

equalizing beam .

6 . Remove the saddle caps, refer to Saddle Cap Assembly in this section .

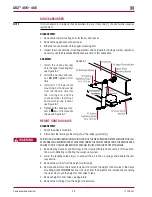

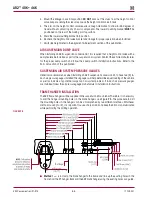

FIguRE 26

7 . Raise the vehicle’s frame just enough to create a ½" (13 mm) gap between the saddles and

the center bushings . Support the vehicle’s frame at this height .

THE WEIGHT OF THE EQUALIZING BEAM ASSEMBLY IS APPROXIMATELY 155 POUNDS . PRIOR TO

REMOVING THE BEAM END FASTENERS FROM THE EQUALIZING BEAM, SUPPORT THE END OF THE

EQUALIZING BEAM TO PREVENT FROM DROPPING . CARE SHOULD BE TAKEN AT REMOVAL AND

INSTALLATION TO PREVENT PERSONAL INjURY OR DAMAGE TO COMPONENTS .

8 . Support both equalizing beams with floor jacks .

9 . Remove the beam end bolt or shaft (as equipped), see Figure 8-26 .

NOTE

Due to the process necessary to remove the beam end adapters, the adapter can be subjected to

damage .

dO NOT

reuse worn or damaged adapters .