Preventive Maintenance

22

17730-241

AR2

™

40K • 46K

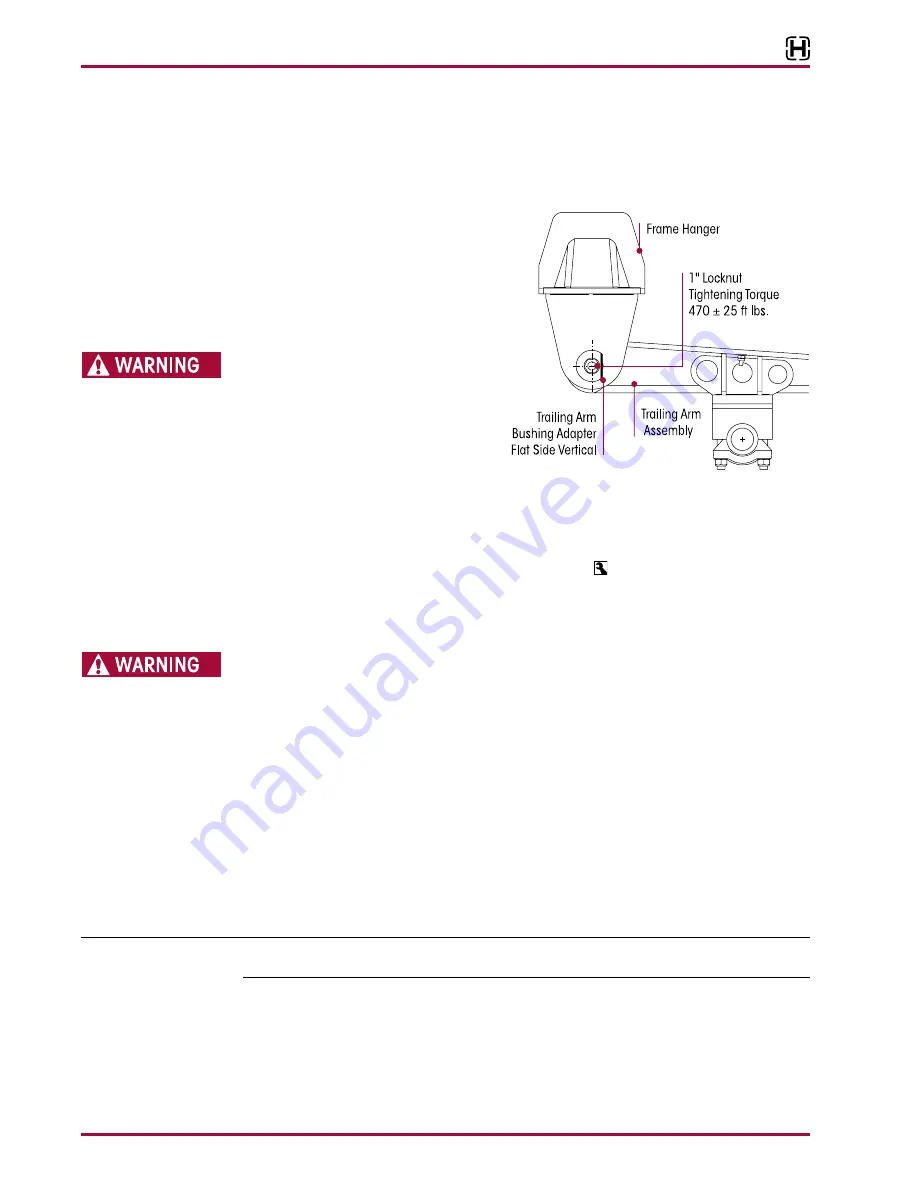

FRAME HANgER TO TRAILINg ARM CONNECTION

If more than half the thickness of the rubber of the trailing arm bushing is diminished replacement

is recommended . For trailing arm bushing replacement, refer to the Component Replacement

section in this publication .

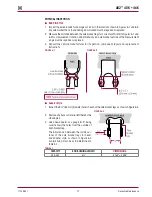

FIguRE 6‑11

■

The flat must be positioned vertically as

shown in Figure

6-11 . If the flat of the

adapter position is incorrect, removal of

the fasteners will be necessary to cor-

rect position .

pHYSICAL INSpECTION

IF TRAILING ARM BUSHING MOVEMENT OR

LOOSENESS IS NOTED IN THE TRAILING ARM

END HUB, DO NOT OPERATE THE VEHICLE .

REPLACE THE RUBBER TRAILING ARM

BUSHINGS AND ALL CONNECTING PARTS . THE

ABOVE CONDITION CAN RESULT IN COSTLY

REPAIR, DOWNTIME, POSSIBLE SEPARATION

OF COMPONENTS, ADVERSE VEHICLE HANDLING, PROPERTY DAMAGE, OR PERSONAL INjURY .

1 . If trailing arm bushing movement or looseness is detected in the trailing arm end hub,

dO NOT

operate the vehicle . Replace the trailing arm bushings and all connecting parts . Refer to the

Component Replacement section of this publication .

2 . Check and record torque values, tighten 1" fasteners to 470 ± 25 foot pounds torque, see

Figure 6-11 .

LONgITudINAL ANd TRANSVERSE TORquE ROdS

THE AR2 SUSPENSION INCORPORATES LONGITUDINAL AND TRANSVERSE RODS FOR VEHICLE

STABILITY . IF THESE COMPONENTS ARE DISCONNECTED OR ARE NON-FUNCTIONAL, THE VEHICLE

SHOULD NOT BE OPERATED . FAILURE TO DO SO CAN RESULT IN ADVERSE VEHICLE HANDLING,

ADVERSE VEHICLE HANDLING, POSSIBLE TIRE CONTACT WITH THE FRAME, PREMATURE COMPONENT

DAMAGE, OR SEVERE PERSONAL INjURY .

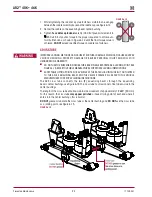

All torque rods need to be inspected for looseness by one of the following methods .

■

Method 1

—

For Tractor applications only

with brakes applied, slowly rock the empty vehicle

with power while a mechanic visually checks the action at both ends

■

Method 2

— with the vehicle shut down, a lever check can be made with a long pry bar placed

under each rod end and pressure applied

Visually inspect torque rod bushings for torn or shredded rubber, inspect for bent, cracked, or

broken torque rods and also for end hubs that have an elongated “oval” shape . Any of these condi-

tions require component replacement . If there is metal-to-metal contact, this is a sign of excessive

bushing wear and the bushing needs to be replaced .

NOTE

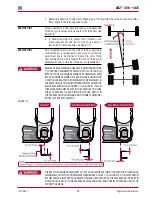

The lengths of the torque rods are determined by the vehicle manufacturer . Refer to vehicle manu-

facturer’s service instructions for the proper torque rod length .

The lengths of these torque rods may be fine tuned by adding or removing shims at the straddle mount

end of the torque rods in order to correct drive line angles or axle centering under the frame . The

transverse torque rods center the axles under the frame and control axle walk-out during cornering .

A two-piece torque rod is also available to cut and weld to the desired length, see Hendrickson

publication No . 45745-148 .

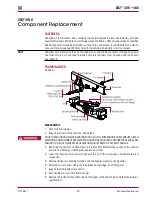

The mounting brackets at the axle ends of the torque rods are furnished and welded into position

on the axle housings by the vehicle manufacturer or the axle manufacturer .