29

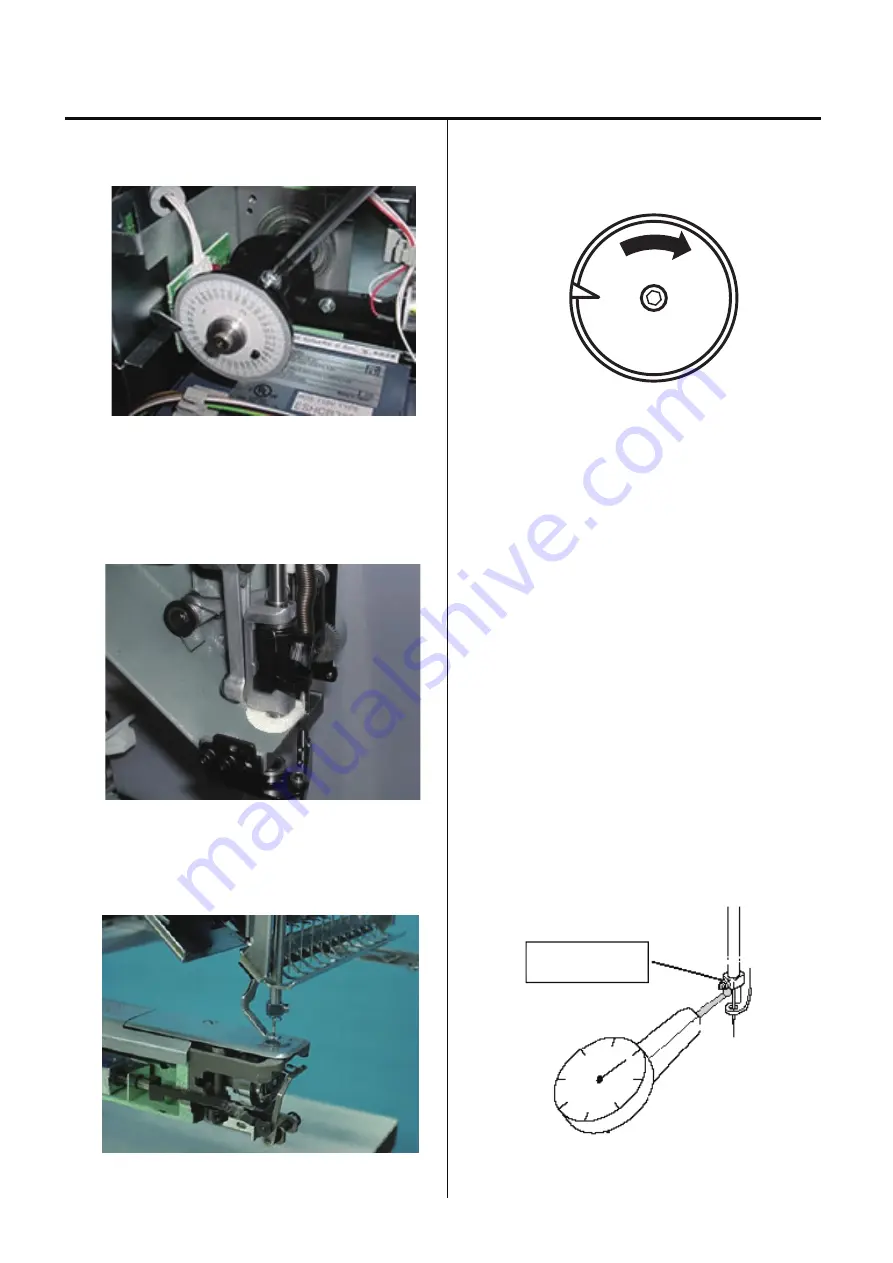

3-2-3 Adjustment of the lowest needle point

1. Loosen screw on detecting disk.

2. Turn upper shaft so that needle bar driver ass’y comes

in the bottom.

In case there is moving head, bring needle bar down.

3. When dial disc reads [

0 degree

], fix detecting disk.

4. Work will finish by checking and adjusting timing

mentioned below.

[ 4-2-1 Upper shaft timing (L point, C point) ]

[ 3-2-8 Take-up lever timing ]

[ 3-5-1 Rotary hook timing ]

[ 3-6-5 Thread cut timing (except (for Rev.A) ))

Please use dial gauge for strict checking.

Please see that timing on dial disc comes to [

0 degree

]

when dial swings in highest value.

Dial-gauge

Needle holder

Содержание HCS2-1201-30

Страница 1: ...Maintenance Manual for Embroidery Machine HCS2 1201 30 Version 2 3 HappyJapan Inc...

Страница 75: ...76 6 Check up with thread trimmer function 7 Assemble lower front panel to terminate this procedure...

Страница 110: ...112 3 7 4 Exchange of Y carriage belt 1 Remove frame base 2 Disconnect X carriage cable 3 Remove X carriage 4 Remove arm...

Страница 154: ...153 5 1 1 Electrical connection diagram except for Rev A...

Страница 155: ...154 5 1 1 Electrical connection diagram except for Rev A...

Страница 156: ...155 5 1 2 List of electrical connection diagrams except for Rev A...

Страница 157: ...156 5 1 3 Electrical connection diagram for Rev A...

Страница 158: ...157 5 1 3 Electrical connection diagram for Rev A...

Страница 159: ...158 5 1 4 List of electrical connection diagrams for Rev A...

Страница 160: ...159 5 2 1 Connection of inverter 100V Inverter set...

Страница 161: ...160 5 2 2 Connection of inverter 200V Inverter set...

Страница 165: ...160c HCD8116 TP switch board ass y 6 5 265 2 1 6 7 257...

Страница 196: ...2017 8 HAPPYJAPAN Inc 9 5 TAITO 2 CHOME TAITO KU TOKYO JAPAN TEL 81 3 3834 0711 FAX 81 3 3835 8917...