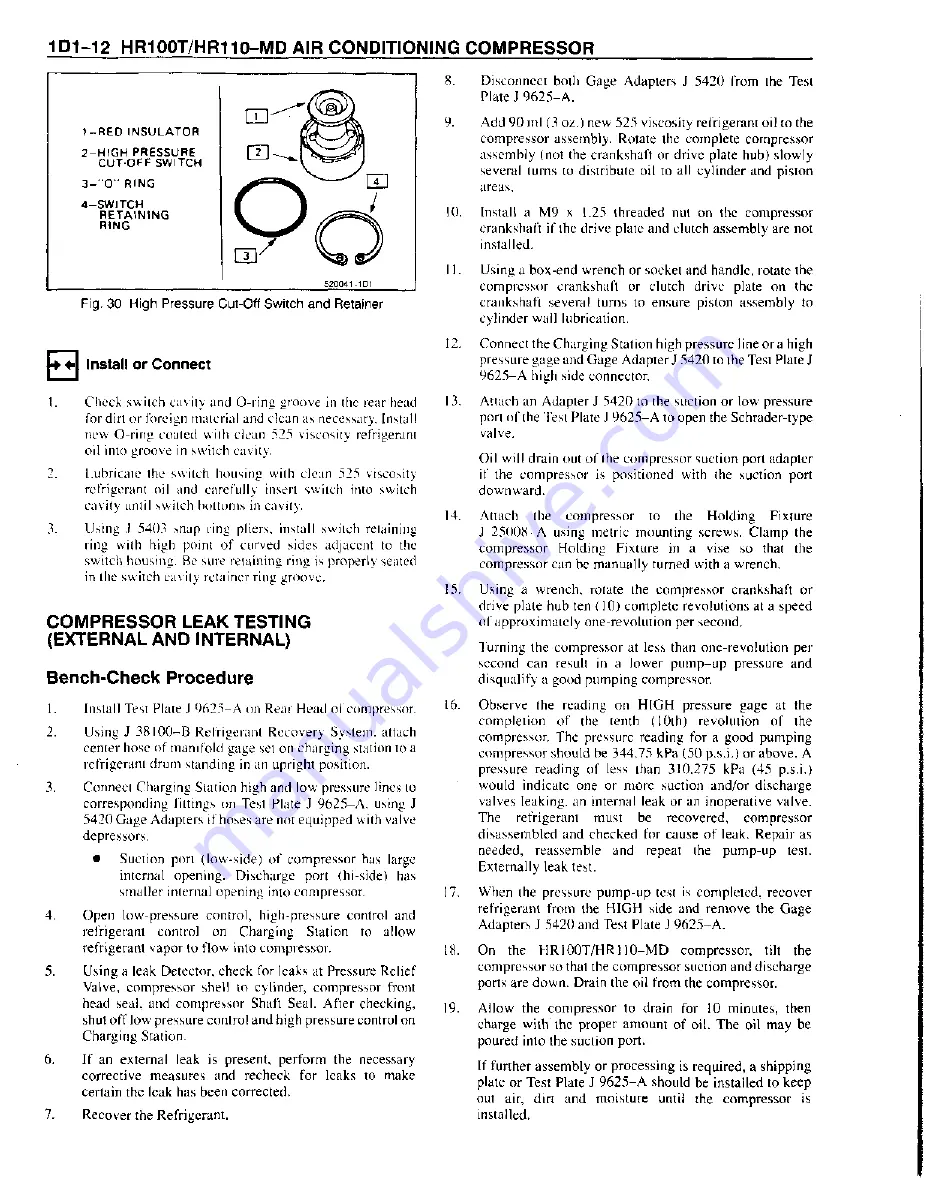

1 - R E D I N S U L A T O R

2 - H I G H P R E S S U R E

C U T O F F S W I T C H

l

' J

3 - " 0 " R I N G

4 - S W I T C H

R E T A I N I N G

R I N G

’ o

520041-1D1

Fig. 30 High Pressure Cut-Off Switch and Retainer

□

Install or Connect

1.

Check sw itch cavity and O -ring groove in the rear head

for dirt or foreign m aterial and clean as necessary. Install

new O -ring coated with clean 525 viscosity refrigerant

oil into groove in sw itch cavity.

2.

Lubricate the sw itch housing with clean 525 viscosity

refrigerant oil and carefully insert switch into switch

cavity until switch bottom s in cavity.

3.

U sing J 5403 snap ring pliers, install switch retaining

ring with high point o f curved sides adjacent to the

sw itch housing. Be sure retaining ring is properly seated

in the sw itch cavity retainer ring groove.

COMPRESSOR LEAK TESTING

(EXTERNAL AND INTERNAL)

Bench-Check Procedure

1.

Install Test Plate J 9 6 2 5 -A on Rear Head o f compressor.

2.

Using J 3 8 1 0 0 -B R efrigerant Recovery System , attach

center hose o f m anifold gage set on charging station to a

refrigerant drum standing in an upright position.

3.

C onnect Charging Station high and low pressure lines to

corresponding fittings on Test Plate J 9 6 2 5 -A , using J

5420 G age A dapters if hoses are not equipped with valve

depressors.

•

Suction port (low -side) o f com pressor has large

internal opening. D ischarge port (hi-side) has

sm aller internal opening into com pressor.

4.

O pen low -pressure control, high-pressure control and

refrigerant control on Charging Station to allow

refrigerant vapor to flow into com pressor.

5.

Using a leak D etector, check for leaks at Pressure Relief

Valve, com pressor shell to cylinder, com pressor front

head seal, and com pressor Shaft Seal. A fter checking,

shut o ff low pressure control and high pressure control on

C harging Station.

6.

If an external leak is present, perform the necessary

corrective m easures and recheck for leaks to make

certain the leak has been corrected.

7.

R ecover the R efrigerant.

8.

D isconnect both Gage A dapters J 5420 from the Test

Plate J 9 6 2 5 -A .

9.

Add 90 ml (3 oz.) new 525 viscosity refrigerant oil to the

com pressor assem bly. Rotate the com plete com pressor

assem bly (not the crankshaft or drive plate hub) slow ly

several turns to distribute oil to all cylinder and piston

areas.

10.

Install a M9 x 1.25 threaded nut on the com pressor

crankshaft if the drive plate and clutch assem bly are not

installed.

11.

Using a box-end w rench or socket and handle, rotate the

com pressor crankshaft or clutch drive plate on the

crankshaft several turns to ensure piston assem bly to

cylinder wall lubrication.

12.

C onnect the Charging Station high pressure line or a high

pressure gage and G age A dapter J 5420 to the Test Plate J

9 6 2 5 -A high side connector.

13.

Attach an A dapter J 5420 to the suction or low pressure

port o f the Test Plate J 9 6 2 5 -A to open the Schrader-type

valve.

Oil will drain out o f the com pressor suction port adapter

if the com pressor is positioned with the suction port

dow nw ard.

14.

A ttach

the

com pressor to

the

H olding

Fixture

J 2 5 0 0 8 -A using m etric m ounting screws. Clam p the

com pressor H olding Fixture in a vise so that the

com pressor can be m anually turned with a wrench.

15.

Using a w rench, rotate the com pressor crankshaft or

drive plate hub ten (10) com plete revolutions at a speed

of approxim ately one-revolution per second.

Turning the com pressor at less than one-revolution per

second can result in a low er p u m p -u p pressure and

disqualify a good pum ping com pressor.

16.

O bserve the reading on HIGH pressure gage at the

com pletion o f the tenth (10th) revolution o f the

com pressor. The pressure reading for a good pum ping

com pressor should be 344.75 kPa (50 p.s.i.) or above. A

pressure reading o f less than 310.275 kPa (45 p.s.i.)

w ould indicate one or m ore suction and/or discharge

valves leaking, an internal leak or an inoperative valve.

The

refrigerant

m ust

be

recovered,

com pressor

disassem bled and checked for cause o f leak. R epair as

needed, reassem ble and repeat the pum p-up test.

Externally leak test.

17.

W hen the pressure pum p-up test is com pleted, recover

refrigerant from the HIG H side and rem ove the G age

A dapters J 5420 and Test Plate J 962 5 -A .

18.

On the H R 100T /H R 110-M D com pressor, tilt the

com pressor so that the com pressor suction and discharge

ports are dow n. Drain the oil from the com pressor.

19.

A llow the com pressor to drain for 10 m inutes, then

charge w ith the proper am ount of oil. T he oil may be

poured into the suction port.

If further assem bly or processing is required, a shipping

plate or Test Plate J 9 6 2 5 -A should be installed to keep

out air, dirt and m oisture until the com pressor is

installed.

Содержание S Series 1994

Страница 1: ......

Страница 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location...

Страница 15: ...G VAN MODELS Rally Sportvan Cutaway Van Extended Van Vandura Chevy Van Magnavan Hi Cube Van F7569...

Страница 17: ...S T PICKUP REGULAR CAB 2 DOOR S T UTILITY VEHICLE S T PICKUP EXTENDED CAB 4 DOOR S T UTILITY VEHICLE 2900r4506...

Страница 24: ...NOTES...

Страница 26: ......

Страница 69: ...NOTES...

Страница 71: ...3 2 STEERING...

Страница 73: ......

Страница 84: ......

Страница 102: ...40...

Страница 130: ...NOTES...

Страница 146: ...NOTES...

Страница 162: ...NOTES...

Страница 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage...

Страница 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential...

Страница 190: ...NOTES...

Страница 202: ...NOTES...

Страница 206: ...F5785...

Страница 209: ...Figure 11 Remove the Pinion Flange F4696 F4759 Figure 14 Removing the Differential Side Bearing...

Страница 212: ...B Button Moved Out of Bearing Bore F5791...

Страница 228: ...NOTES...

Страница 232: ......

Страница 234: ......

Страница 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models...

Страница 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap...

Страница 247: ...C Measure with Axle Shaft Forced Outboard 1 Shaft 5 Tube 9 Carrier Connector 23 Output Shaft 29 Carrier Case F5877...

Страница 261: ...F7475...

Страница 267: ...B Button Moved Out of Bearing Bore F5791...

Страница 294: ...NOTES...

Страница 300: ...NOTES...

Страница 318: ...NOTES...

Страница 322: ...SR207LN2 EDS...

Страница 324: ......

Страница 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS...

Страница 368: ...103 153 127 V1200...

Страница 370: ......

Страница 372: ......

Страница 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft...

Страница 375: ...Front View Rear View Showing Path Of Oil To Timing Chain Showing Main Gallery Oil Filter And Crankshaft Oil Feed V0575...

Страница 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft...

Страница 399: ...V2974...

Страница 410: ......

Страница 412: ...195 196 201 174 252 163 165 164 244 3706r3924...

Страница 452: ......

Страница 454: ...163 164 V1202...

Страница 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196...

Страница 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204...

Страница 460: ......

Страница 510: ......

Страница 512: ...V2131...

Страница 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751...

Страница 516: ...259 260 150 237 S lM 180 167180 J 1 82 183 170 169 1 1 78 1 7 9 213212 2 0 7 205 r i 3706r4752...

Страница 566: ...NOTES...

Страница 574: ...NOTES...

Страница 618: ...SPECIAL TOOLS...

Страница 620: ...NOTES...

Страница 672: ......

Страница 682: ......

Страница 686: ......

Страница 689: ...SPRINGS LOCATED IN THE PUMP PRESSURE CONV CL REGULATOR VALVE SPRINGS LOCATED IN THE VALVE BODY 3 4 SHIFT...

Страница 694: ...RH0213 4L60 E...

Страница 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E...

Страница 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E...

Страница 697: ...SPECIAL TOOLS...

Страница 698: ...SPECIAL TOOLS...

Страница 758: ...RH0194 4L80 E...

Страница 764: ......

Страница 770: ...SPECIAL TOOLS...

Страница 771: ...SPECIAL TOOLS CONT...

Страница 772: ......

Страница 775: ......

Страница 776: ......

Страница 785: ......

Страница 804: ...NOTES...

Страница 806: ......

Страница 808: ......

Страница 822: ...3707r5079...

Страница 840: ......

Страница 848: ...NOTES...

Страница 852: ......

Страница 859: ...17 Rear Case Half 18 Oil Pump Pick Up Tube 26 Connector Dowel Pin Location Pump Pick Up Screen F5434...

Страница 860: ...F5435...

Страница 866: ......

Страница 878: ...F9167...

Страница 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836...

Страница 890: ...F9168...

Страница 908: ......

Страница 914: ...J 2619 01 46 Rear Case 85 Front Output Shaft Rear Bearing F7659 Figure 21 Removing the Front Output Shaft Rear Bearing...

Страница 919: ......