71

10.1.4 200 Hour Lubrication Interva

l

Wheel Bearings

Every 200 hours (or yearly), repack the wheel bearings

using a good quality wheel bearing grease.

10.2 Maintenance

10.2.1 General

Repair or replace damaged or broken parts immediately.

Check all safety and operating decals. If any decals are

illegible or missing, replace any decals immediately. DO

NOT operate sprayer with missing or damaged decals.

Refer to the “Safety Decal” section of this manual for all

safety decal locations. Refer to your parts manual for all

operating decals.

10.2.2 Fasteners

After the first hour of use, check all the fasteners and tighten

any found to be loose. Thereafter, check all fasteners

periodically and tighten as required.

10.2.3 Tire Pressure

Check the tire pressure daily.

The recommended tire pressure is:

12.4-24 6 ply tires .............................. 24 psi

11.2-38 4 ply tires .............................. 18 psi

13.6-38 12 ply tires ............................ 42 psi

10.2.4 Filters

Remove and clean the water filters daily. Clean the filters on

the optional foam marking system at intervals as specified

in the foam system owner’s manual.

IMPORTANT: Always wear gloves and eye protection while

servicing the sprayer.

To manually clean the self cleaning filter:

1. Make sure the product pump is turned OFF.

2. Close the emergency shut off valve under the product

tank.

3. Make sure the agitation valve and self cleaning filter

bypass agitation valve are both closed.

4.

Place a clean empty container under the filter base to

catch any water and chemicals.

5.

Very carefully disconnect the bypass line from the

bottom of the filter and allow the water and chemicals to

flow into the container.

6.

Remove the canister from the filter head by rotating

counter clockwise.

7. Rinse the canister and screen in clean water.

8. Before reinstalling the canister to the filter head, lubricate

the canister O-ring with clean engine oil. Reinstall the

canister and hand tighten only.

9. Connect the bypass hose to the bottom of the filter, open

the bypass and agitation valves. Open the emergency

shut off valve at the bottom of the product tank.

10. Start the sprayer pump with water in the tank and check

for leaks.

11. This procedure also applies to sprayer equipped with

the standard filter.

10.2.5 Sprayer Tips

Refer to the information “Spray Tip Wear” for tip cleaning.

10.3 Storing and Winterizing

Storing your sprayer properly during the off season will help

reduce the time needed to get the sprayer ready for the next

spraying season. If at all possible, store your prayer in a dry

building to protect it from the harmful effects of the weather.

Ultraviolet light in the sun’s rays softens and weakens

rubber used for hoses and tires.

^

WARNING

Wear protective clothing (such as goggles,

rubber or chemical resistant gloves and a

respirator) while handling or working with

chemicals. Keep protective clothing clean and

in good condition or discard.

IMPORTANT: It is very important that you thoroughly clean

the sprayer inside and out.

Cleaning the Inside of the sprayer

1. Add about 50 gallons of clean water along with a

Neutralizing agent into the sprayer product tank. Refer

to “Cleaning the Sprayer” in this manual.

2. Start the product pump and run at rated volume.

3. Open and close ALL valves on the sprayer to ensure

you have clean water through the entire system.

NOTE: The pressure gauge hose is supplied from the rear

of the sprayer and is a “dead end” circuit. The following

procedure is recommended for cleaning.

Содержание BW750

Страница 18: ...18...

Страница 19: ...19 Decal A Decal B Decal C Decal D...

Страница 20: ...20 Decal E Decal F Decal G Decal H Decal I Decal J...

Страница 21: ...21 Decal K Decal L...

Страница 36: ...36 9 6 Spray Tip Wear...

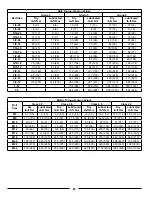

Страница 43: ...43 9 8 TeeJet Air Induction Spray Tips 9 8 1 20 Inch Spacing At Various Speeds And Pressures...

Страница 49: ...49 9 10 TeeJet FloodJet Wide Angle Flat Spray Tips 9 10 1 40 Inch Spacing At Various Speeds And Pressures...

Страница 57: ...57 Instructions Valve Settings For Accessory Kits Refer To The Operator s Manual For Detailed Instructions...

Страница 81: ...81 12 3 Raven Console Calibration Information...

Страница 83: ...83 Notes...