66

4. Locate the electric control switch on the tractor control

box and move the switch to “Rinse Balls” or “Product

Tank Rinse” and let run until you have used a third of

the water in the clean water rinse tank.

5.

On the tractor control box, move the “Rinse Balls”

switch to the “Product Tank” position (HC control) and/

or “Product Tank Rinse” switch to the “OFF” position and

the “Product Tank”/ “Rinse Tank” switch to the “Product

Tank” position (Standard electric control).

6.

Drive at normal speed, turn complete boom on and

spray as normal until product tank is empty.

7. Repeat the cleaning procedure two more times to

ensure proper cleaning.

9.29.3 Cleaning Your Sprayer Manually

Keeping your sprayer clean helps assure a long service

life. Many pesticides can quickly corrode metal parts in the

spraying system. Chemicals remaining in the sprayer can

react with a second chemical introduced to the system and

offset its effectiveness.

Following are instructions for cleaning your sprayer if it is

not equipped with a factory installed rinse system.

1. Select an area where the cleaning solution can be

safely sprayed out of the system.

2. Check the label on the chemical container for specific

cleaning instructions.

3.

Wash the entire sprayer system using a water hose

and a brush. Use a soft brush to clean nozzle tips and

screens.

4. Flush with clean water.

5.

Dispose of the cleaning solution properly according to

local regulatory agency requirements.

9.30 Hydraulic Boom Operation

Three types of hydraulically operated booms are available.

They are EF Booms, EFT Booms and HC Booms.

^

DANGER

To avoid personal injury or death, KEEP clear

of ALL electrical power lines when operating

sprayer or when folding or unfolding booms.

^

WARNING

To avoid personal injury, make sure that

everyone is at a safe distance from the sprayer

before folding or unfolding the sprayer boom.

Keep a safe distance from the boom while

in operation. Hydraulic booms may move

suddenly without warning.

9.30.1 EF & EFT Boom

After the sprayer and hydraulic hoses have been properly

attached to the tractor, unfold the boom using the following

procedure:

1. Raise the complete boom until the boom wings clear the

transport rest.

2. Place the tractor in park and/or set the brakes and stop

the engine.

3. Remove the transport lock from the lift cylinder at the

rear of the sprayer and place in the storage position

provided.

4.

Restart the tractor and unfold the boom wings until the

boom is in the working position.

5. Lower the entire boom to the desired height.

IMPORTANT: DO NOT lower boom to the full down position.

There must be a minimum of 1-1/2” of hydraulic lift cylinder

shaft showing before the suspension can work properly.

1 - Transport Lock

2 - Hydraulic Lift Cylinder

Содержание BW750

Страница 18: ...18...

Страница 19: ...19 Decal A Decal B Decal C Decal D...

Страница 20: ...20 Decal E Decal F Decal G Decal H Decal I Decal J...

Страница 21: ...21 Decal K Decal L...

Страница 36: ...36 9 6 Spray Tip Wear...

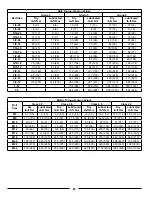

Страница 43: ...43 9 8 TeeJet Air Induction Spray Tips 9 8 1 20 Inch Spacing At Various Speeds And Pressures...

Страница 49: ...49 9 10 TeeJet FloodJet Wide Angle Flat Spray Tips 9 10 1 40 Inch Spacing At Various Speeds And Pressures...

Страница 57: ...57 Instructions Valve Settings For Accessory Kits Refer To The Operator s Manual For Detailed Instructions...

Страница 81: ...81 12 3 Raven Console Calibration Information...

Страница 83: ...83 Notes...