34

D. After 50 hours of operation:

1. Tighten all wheel lugs to 135 lb/ft of torque.

2.

Then follow normal servicing and maintenance

schedule as defined in Maintenance Section.

9.3 Pre-Operation Checklist

Efficient and safe operation of the Fast Manufacturing, Inc.

Sprayer requires that each operator reads and understands

operating procedures and all related safety precautions

outlined in this section. A pre-operational checklist is

provided for the operator. It is important for both personal

safety and maintaining the good mechanical condition of

the sprayer that this checklist be followed.

Before operating sprayer, check the following items:

1.

Lubricate machine per schedule outlined in “Maintenance

Section”.

2. Use only a tractor of adequate power and weight to

operate sprayer.

3.

Be sure that machine is properly attached to tractor.

Be sure that a mechanical retainer is installed through

drawbar pin and safety chain is installed.

4.

Inspect all hydraulic lines, hoses, fittings and couplers

for tightness.

5.

Check tires and verify they are inflated to specified

pressure.

6.

Calibrate sprayer if at start of season or a new sprayer

rate is being used.

7. Check condition and routing of all fluid hoses and lines.

Be sure that all lines are routed in large arcs. Replace

any that are damaged. Re-route those that are rubbing,

pinched or crimped.

8. Check placement components. Remove and replace

any that are worn.

9. Remove all entangled material.

9.4 Measuring Travel Speed

Measure a test course in the area to be sprayed or in an

area with similar surface conditions. Minimum lengths of

100 and 200 feet are recommended for measuring speeds

up to 5 and 10 miles per hour, respectively. Determine the

time required to travel the test course.

To help ensure accuracy, conduct the speed check with a

loaded sprayer and select the engine throttle setting and

gear that will be used when spraying. Repeat the above

process and average the times that were measured. Use

the following equation or the table to determine ground

speed.

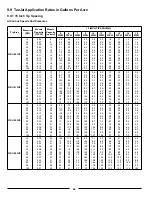

Speed

(mph)

Travel Time Required (seconds)

100 Feet

200 Feet

300 Feet

3.0

23

45

68

3.5

20

39

58

4.0

17

34

51

4.5

15

30

45

5.0

14

27

41

6.0

-

23

34

7.0

-

19

29

7.5

-

18

27

8.0

-

17

26

9.0

-

15

23

Useful Formulas and Conversions

GPA=

Application rate in gallon per acre

GPM=

Flow rate in gallons per minute

S=

Speed in miles per hour

W=

Nozzle spacing in inches

Calculate flow rate per nozzle when application rate, speed

and nozzle spacing are known:

GPM (per Nozzle) = GPA x S x W

5940

Calculate application rate when nozzle spacing, speed and

flow rate are known:

GPA = 5940 x GPM

S x W

Calculate speed when flow rate, application rate and nozzle

spacing are known:

S = 5940 x GPM

GPA x W

Convert speed from feet per second to miles per hour:

S = Feet per second x 0.682

9.4.1 Spraying Solutions Other Than Water

Since all the tabulations are based on spraying water,

which weighs 8.34 lbs. per US gallon, conversion factors

must be used when spraying solutions which are heavier

or lighter than water. To determine the proper size nozzle

for the solution to be sprayed, first multiply the desired

GPM or GPA of solution by the water rate conversion factor.

Then use the new converted GPM or GPA rate to select the

proper size nozzle.

Содержание BW750

Страница 18: ...18...

Страница 19: ...19 Decal A Decal B Decal C Decal D...

Страница 20: ...20 Decal E Decal F Decal G Decal H Decal I Decal J...

Страница 21: ...21 Decal K Decal L...

Страница 36: ...36 9 6 Spray Tip Wear...

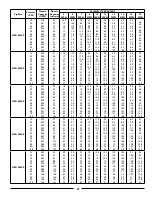

Страница 43: ...43 9 8 TeeJet Air Induction Spray Tips 9 8 1 20 Inch Spacing At Various Speeds And Pressures...

Страница 49: ...49 9 10 TeeJet FloodJet Wide Angle Flat Spray Tips 9 10 1 40 Inch Spacing At Various Speeds And Pressures...

Страница 57: ...57 Instructions Valve Settings For Accessory Kits Refer To The Operator s Manual For Detailed Instructions...

Страница 81: ...81 12 3 Raven Console Calibration Information...

Страница 83: ...83 Notes...