48

3. By using the up or down arrows the calibration

temperature can be c or - 35 degrees.

4. When the desired calibration is reached, touch the

cancel pad to return the control to normal operation.

TROUBLESHOOTING

The ES 200 has some self diagnostics built into the

microprocessor to help in troubleshooting the system.

When a failure occurs one of three codes will appear

in all the display windows: F1, F3 or F9.

F1 code:

F1 indicates a malfunction in the control itself, and the

control should be replaced.

F3 code:

F3 indicates a defective sensor, electronic oven control

or the wiring in between. To determine which part is

defective:

1. Disconnect the 15 pin plug from the back of the oven

control that connects the sensor to the oven control.

2. With an Ohmmeter measure the resistance between

pins 12 and 13 in the plug

(not on the control

board)

.

If the meter reads around the value of the

oven temperature sensor resistance chart, the oven

control is defective. If the meter reads less than 800

Ohms or more than 3000 Ohms, go to step 3.

3. Disconnect the harness from the oven sensor and

measure the resistance of the oven sensor. If the

reading is the same as that in step two the oven

sensor is defective. If the reading is correct with

the chart the harness is defective.

F9 code:

F9 code indicates the control has detected a problem

with the motor door latch assembly. Check the contacts

of the lock switch, wiring to the lock motor assembly,

and the lock motor.

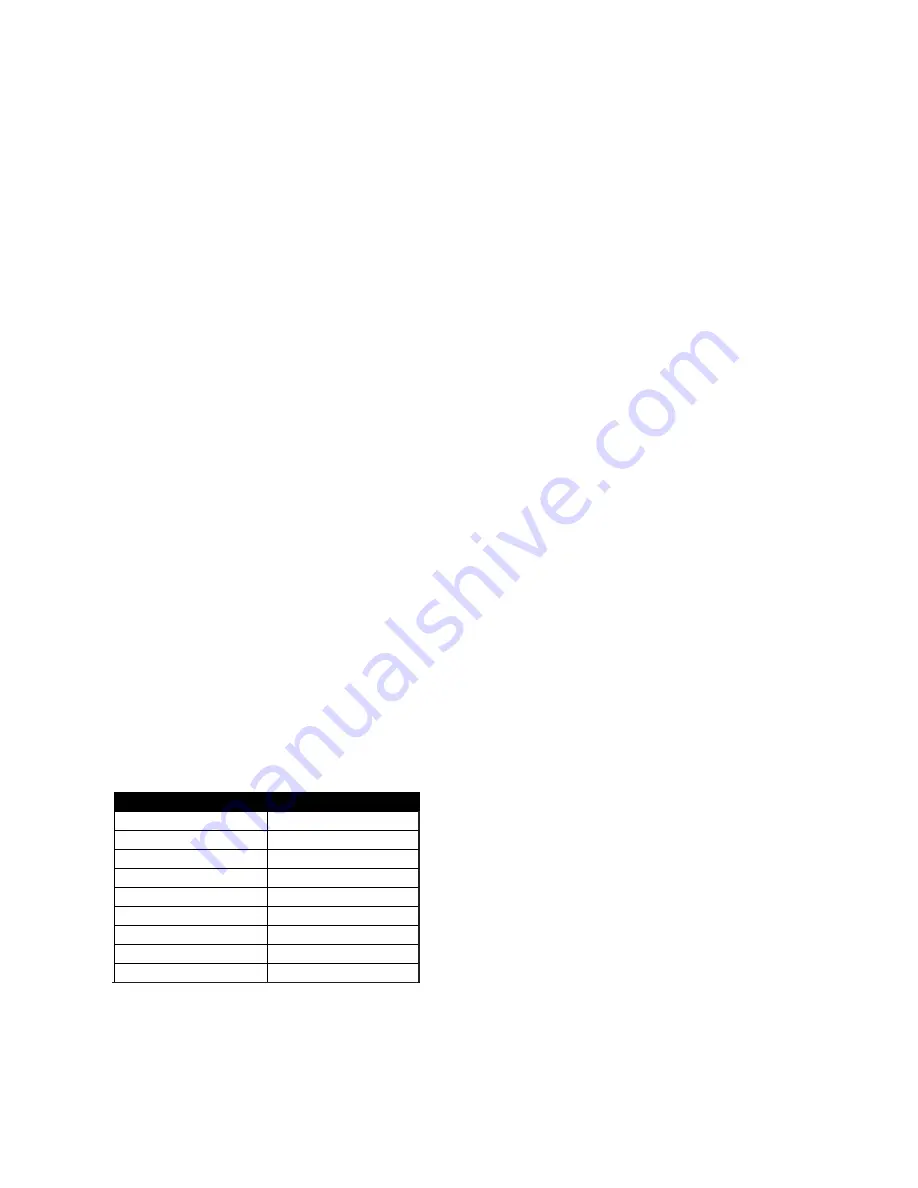

RTD SCALE

Temperature (°F)

Resistance (ohms)

32 ± 1.9

1000 ± 4.0

75 ± 2.5

1091 ± 5.3

250 ± 4.4

1453 ± 8.9

350 ± 5.4

1654 ± 10.8

450 ± 6.9

1852 ± 13.5

550 ± 8.2

2047 ± 15.8

650 ± 9.6

2237 ± 18.5

900 ± 13.6

2697 ± 24.4

Control will not program:

If the control will not program check for an open sensor

circuit. If the sensor circuit is good replace the control.

Blank Display:

If the display on the oven control is blank, with the

range connected to electrical power:

1. Go to the back of the control, disconnect the 15 pin

plug and measure the voltage drop between pins 4

and 5 in the plug. If the meter reads line to neutral

voltage (120 VAC) the control is defective. If the

meter reads zero the wiring in the range is defective.

No heat:

If the control appears to be operating normally,

but the bake and broil burners do not heat:

1. Program the control for bake and check to see if

the bake igniter is glowing. If the igniter is not

glowing, go to step 3. If the igniter is glowing check

the manual gas shut-off for the oven to be sure gas

is being supplied to the safety valve. Then remove

the bake igniter, connect it to 120 VAC and measure

the current flow through the igniter. If the current

flow is less than 3.2 amps replace the igniter. If the

current flow is 3.2 or more check the wiring in the

bake circuit for a poor connection.

2. Program the control for broil and check to see if the

broil igniter is glowing. If the igniter is not glowing

go to step 4. If the igniter is glowing remove the

igniter, connect it to 120 VAC and measure the

current flow through the igniter. If the current flow is

less than 3.2 amps replace the igniter. If the

current flow is 3.2 or more check the wiring in the

broil circuit for a poor connection.

3. Go to the back of the oven control, disconnect the

15 pin plug from the control and measure the voltage

drop between pins 1 and 4 in the 15 pin plug. If the

meter reads 120 VAC the control is defective. If the

meter reads zero the bake igniter, safety valve or

the wiring in the oven circuit is open. Go to step 5.

4. Go to the back of the oven control, disconnect the

15 pin plug from the control and measure the voltage

drop between pins 2 and 4 in the 15 pin plug. If the

meter reads 120 VAC the control is defective. If the

meter reads zero the broil igniter, safety valve or the

wiring in the broil circuit is open. Go to step 5.

5. Disconnect the wires from the igniter and check it

for continuity with an Ohmmeter. If the meter reads

Содержание 30" GAS FREESTANDING RANGES

Страница 43: ...43 SAMPLE SCHEMATIC FOR ES100 CONTROL SYSTEM ...

Страница 50: ...50 SAMPLE SCHEMATIC FOR ES 200 CONTROL SYSTEM ...

Страница 60: ...60 SAMPLE SCHEMATIC FOR ES 300 CONTROL SYSTEM ...

Страница 72: ...72 SAMPLE SCHEMATIC FOR ES 400 CONTROL SYSTEM ...

Страница 84: ...84 SAMPLE SCHEMATIC FOR ES 450 CONTROL SYSTEM ...

Страница 93: ...93 Sample schematic for 36 gas range ...

Страница 130: ...130 NOTES ...

Страница 131: ...131 NOTES ...

Страница 132: ...132 ...