INCL

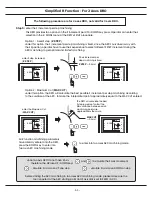

function - To swing the tool turret on the cross slide for conical machining

To machine a conical work piece as per the diagram shown, it is the most basic that we have to swing the

cross slide of the tool turret accurately at the incline angle that we have to machine.

Most of the tool turret on the lathe have an

angular dial allow the operator to swing the

tool turret to the angle that required. However,

this angular dial is usually very corse and not

accurate enough.

Conical Machining on Lathe

to swing the tool

turret for conical

machining

Example :

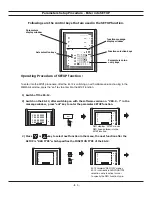

To accuractely swing the tool turret on the cross slide by -20 degree, so that the operator can make

to conical machining as per following diagram shown.

Angular direction :

positive ( clockwise )

negative ( counter clockwise )

Z (+) or Y(+)

X(+)

Directional Notations

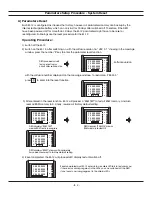

Step 1 :

Swing the tool turret to 20 degree accordining to the angular dial of the tool turret, swing it to the angle

of 20 degree as accurate as possible, remove the cutting tool and put a dial indicator onto the tool

turret, install a bar on the lathe as shown.

angular dial

( usually very corse,

not accurate enough )

install a bar on the lathe

angular dial, swing

the tool turret to 20

degree as accurate

as possible.

0

place a dial indicator

onto tool turret and pointing

perpendicular to the bar

- A. 5 -

bar

Содержание ES-12

Страница 1: ...Always Committed to Quality Technology Innovation ES 12 Digital Readout System Operation Manual...

Страница 8: ...1 Basic Fucntions Basic Functions BASIC...

Страница 15: ...8 Built in Calculator Calculator...

Страница 27: ...20 REF datum memory...

Страница 31: ...24 LHOLE tool positioning for the Line Holes...

Страница 35: ...28 INCL Inclined angle tool positioning...

Страница 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Страница 45: ...R R R 38 tool positioning for ARC machining...

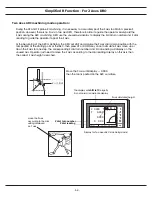

Страница 63: ...R R R 56 Simplified R function...

Страница 73: ...66 Shrinkage Calculation L L X 1 005...

Страница 91: ...Parameter Setup B 1 SET UP...