1

2

3

4

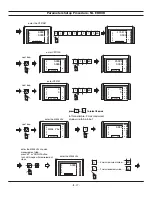

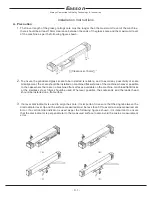

CP. START

Error

error curve

start position

( must be locate

at the most

negative position

of the machine )

CP. PITCH

CP. STEP=10

error curve

Position

(+Direction)

REF

mark

5

6

7

8

9

10

ref

abs

inc

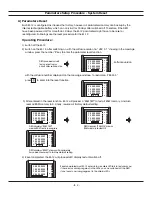

Parameters Setup Procedure - NL ERROR

NL ERROR menu is designed to allow user to enter the Non Linear Error Compensation value into the DRO, so that

the DRO can compensate virtually all type of error in the machine. With DRO's non linear error compensation

function, as long as the position repeatability of the machine is good, it can greatly improve the machine

accuracy. This feature is very useful in the application which demand very high machine accuracy. Such as

Grinder application, Borer application amd etc..

Principle of Operation.

Non Linear Error Compensation make use of the REF ( reference mark ) position of the linear scale to provide a fixed

position as absolute zero of the machine. The DRO's CPU then compensat the readout readings according to the

error table that built during this SETUP process. The compensation always started at the error curve start position as per

the digram below. It is vital important to have the CP-START. position located at the most negative position of the machine,

so that most of the machine travel range are covered by the non-linear error compensation. This DRO software offer

non-linear error compensation in both X and Y axes, Maximum of 62 compensation steps is possible for each axis.

Please notice that, after the non-linear compensation is in active, the linear compensation is not active any more.

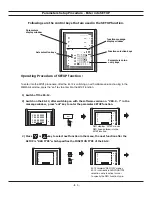

CP. START :

CP. PITCH :

CP. STEP :

Compensation

Profile Start

Compensation

Profile Pitch

Compensation

Profile Step

Operation Procedure

1) Locate the REF zeto at ABS coordinate :

swap the readout display

to ABS coordinate

Enter into

ref

function

select the FIND REF ( find

ref

mark )

- B. 13 -

X

Y

Z

SDM 5

mm

mm

mm

56.785

12.345

0.000

X

Y

Z

ABS

mm

mm

mm

0.000

86.650

52.450

X

Y

Z

ABS

mm

mm

mm

0.000

86.650

52.450

X

Y

Z

ABS

RECALL 0

mm

mm

mm

X

Y

Z

ABS

FIND REF

mm

mm

mm

Содержание ES-12

Страница 1: ...Always Committed to Quality Technology Innovation ES 12 Digital Readout System Operation Manual...

Страница 8: ...1 Basic Fucntions Basic Functions BASIC...

Страница 15: ...8 Built in Calculator Calculator...

Страница 27: ...20 REF datum memory...

Страница 31: ...24 LHOLE tool positioning for the Line Holes...

Страница 35: ...28 INCL Inclined angle tool positioning...

Страница 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Страница 45: ...R R R 38 tool positioning for ARC machining...

Страница 63: ...R R R 56 Simplified R function...

Страница 73: ...66 Shrinkage Calculation L L X 1 005...

Страница 91: ...Parameter Setup B 1 SET UP...