PCD

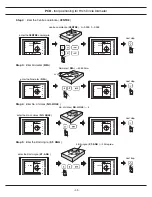

- tool positioning for Pitch Circle Diameter

- 36 -

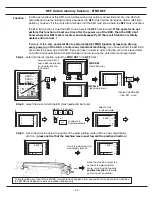

next Pitch Hole

previous Pitch Hole

move the machine to axes display

= ( 0.000, 0.000 )

move the machine to axes display

= ( 0.000, 0.000 )

HOLE 2 = Pitch Hole no. 2

HOLE 1 = Pitch Hole no. 1

all PCD machining parameters to enter into the PCD machining mode

already entered into the DRO

operator can press or to select the Pitch Hole's number, and move the machine to

display = 0.000, then the Pitch Hole position is reached.

2

1

1

4

5

3

1

3

2

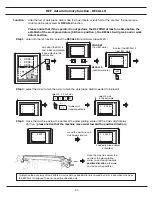

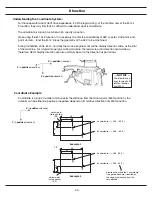

Step 6

: Enter the End Angle (

End. ANG

)

enter the End angle (

ENd. ANG

)

End angle (

ENd. ANG

) = 300 degree

X

Y

Z

ABS

END. ANG

PCD

0.000

Y

X

END.ANG

X

Y

Z

ABS

END. ANG

PCD

300.000

Y

X

END.ANG

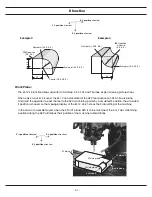

X

Y

Z

ABS

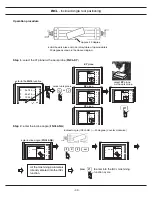

XY=0: HOLE 2

PCD

0.000

0.000

0.000

Y

X

X

Y

Z

ABS

XY=0: HOLE 1

PCD

0.000

0.000

0.000

Y

X

Содержание ES-12

Страница 1: ...Always Committed to Quality Technology Innovation ES 12 Digital Readout System Operation Manual...

Страница 8: ...1 Basic Fucntions Basic Functions BASIC...

Страница 15: ...8 Built in Calculator Calculator...

Страница 27: ...20 REF datum memory...

Страница 31: ...24 LHOLE tool positioning for the Line Holes...

Страница 35: ...28 INCL Inclined angle tool positioning...

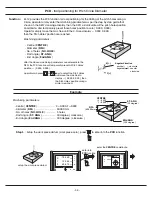

Страница 40: ...33 PCD tool positioning for Pitch Circle Diameter...

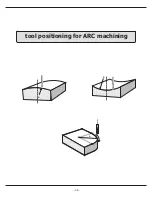

Страница 45: ...R R R 38 tool positioning for ARC machining...

Страница 63: ...R R R 56 Simplified R function...

Страница 73: ...66 Shrinkage Calculation L L X 1 005...

Страница 91: ...Parameter Setup B 1 SET UP...