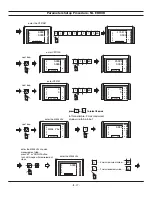

A

B

C

18

0.2

3

0

.5

0

.1

2

5

0

.1

0

0.2

0.1 F

0.1 F

0.05

0.05

0.1

0.05

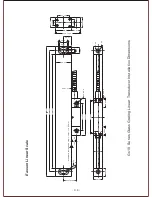

L

950mm

L

950mm

"

0.2

F

-

0.1

"

0.2

F

-

0.1

B. Installation standards & Requirements

1. Requirements for the mounting surface

a) If the scale mounting surfaces are not parallel to each other (i.e. As per shown in figure A and B),

the parallelism of the two mounting surfaces must be less than 0.1mm.

b) If the mounting surfaces are perpendicular to each other. (I.e.As per shown in figure c), the squareness

of these two mounting surfaces must be less than 0.1mm.

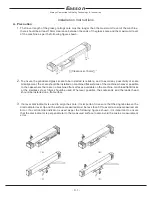

2. Scale Alignment

It is very important that the scale must be aligned parallel to the travel of the machine slide.

For scale travel less than 950mm, the maximum parallel error between the scale and the machine

slide must be less than 0.1mm 0.15mm.

For scale travel longer than 950mm, the maximum alignment parallelism error must be less that 0.1mm.

Always Committed to Quality Technology & Innovation

Easson

- C. 4 -

Содержание ES-12

Страница 1: ...Always Committed to Quality Technology Innovation ES 12 Digital Readout System Operation Manual...

Страница 8: ...1 Basic Fucntions Basic Functions BASIC...

Страница 15: ...8 Built in Calculator Calculator...

Страница 27: ...20 REF datum memory...

Страница 31: ...24 LHOLE tool positioning for the Line Holes...

Страница 35: ...28 INCL Inclined angle tool positioning...

Страница 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Страница 45: ...R R R 38 tool positioning for ARC machining...

Страница 63: ...R R R 56 Simplified R function...

Страница 73: ...66 Shrinkage Calculation L L X 1 005...

Страница 91: ...Parameter Setup B 1 SET UP...