91

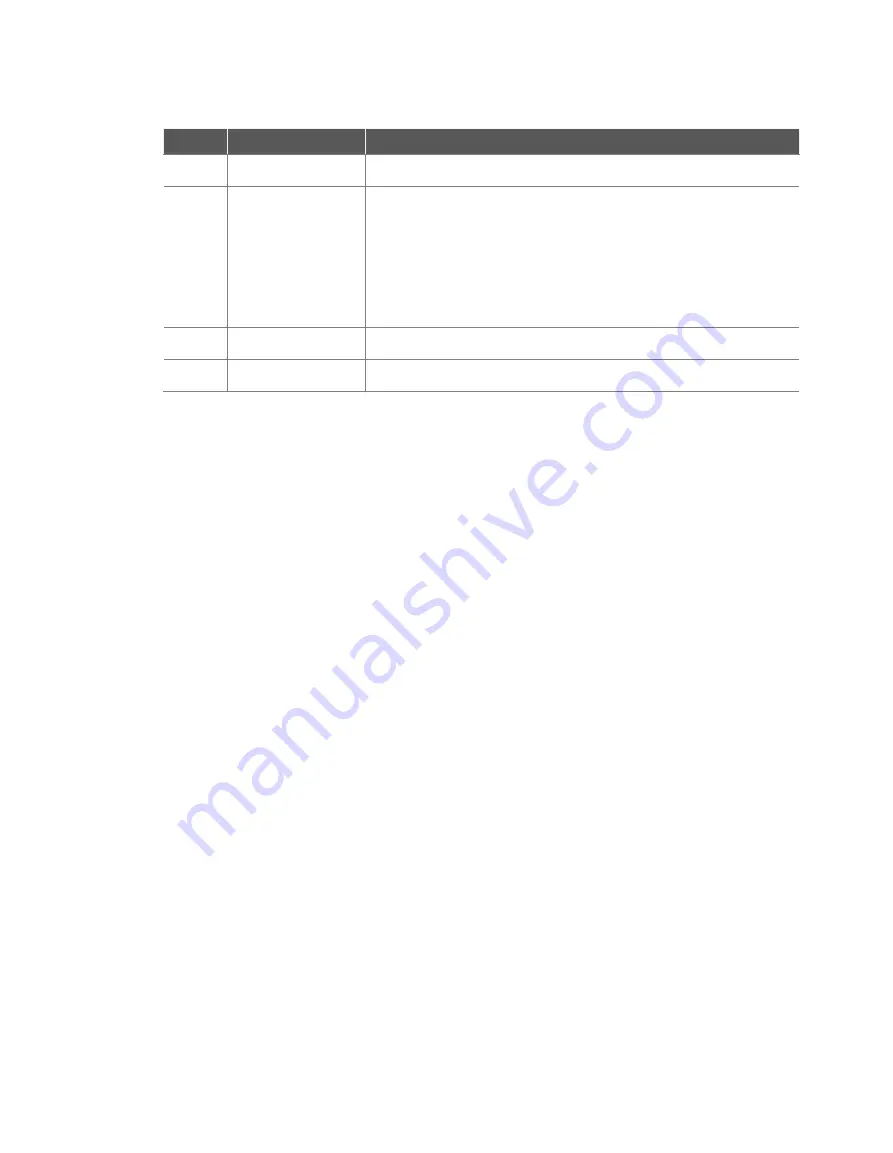

No.

Item

Description

Port Number

: Select the end effector output signal port.

Operation

: Tests the output signal status.

5

Input Signal

Checks and sets the input signal.

Input Signal

: Sets the output signal type (control box, flange,

Modbus).

Name

: Displays the output signal name. The signal can be turned on

or off by pressing the toggle button.

Port Number

: Select the end effector output signal port.

Operation

: Displays the input signal status. If the signal is normal, it

is displayed as green.

6

Delete

Deletes the end effector being configured.

7

Confirm

Saves the setting.

Tools include a screwdriver, gluing tool, deburring tool, and polish and air blow nozzle, and there is

also a custom tool setting function to allow the use of other user tools. Configuring tool settings is

similar to that of gripper settings.

For more information about each tool setting, refer to the separate manuals provided.

Содержание M0609

Страница 1: ...Manual Version 1 9 Software Version 2 5 ...

Страница 21: ...21 For information about additional modules refer to corresponding manuals ...

Страница 59: ...59 Tapping the Edit button cannot edit the setting but deletion is possible ...

Страница 61: ...61 No Item Description 9 Delete Deletes the current Workcell 10 Confirm Saves the Workcell settings ...

Страница 75: ...75 A Series does not feature Auto Calculate for weight ...

Страница 97: ...97 Note The configuring end effector and base end effector must be symmetrical on the tool Z axis ...

Страница 133: ...133 4 The Save As popup window appears Enter the task name in the popup window and tap the Confirm button ...

Страница 139: ...139 9 5 Execute Task Program The execution of task programs in Task Writer is identical to that of Task Builder ...

Страница 166: ...Doosan Robotics User Manual v1 9 166 ...

Страница 190: ...Doosan Robotics User Manual v1 9 190 ...