Chapter 10 Troubleshooting

10-4

Revision June 2010

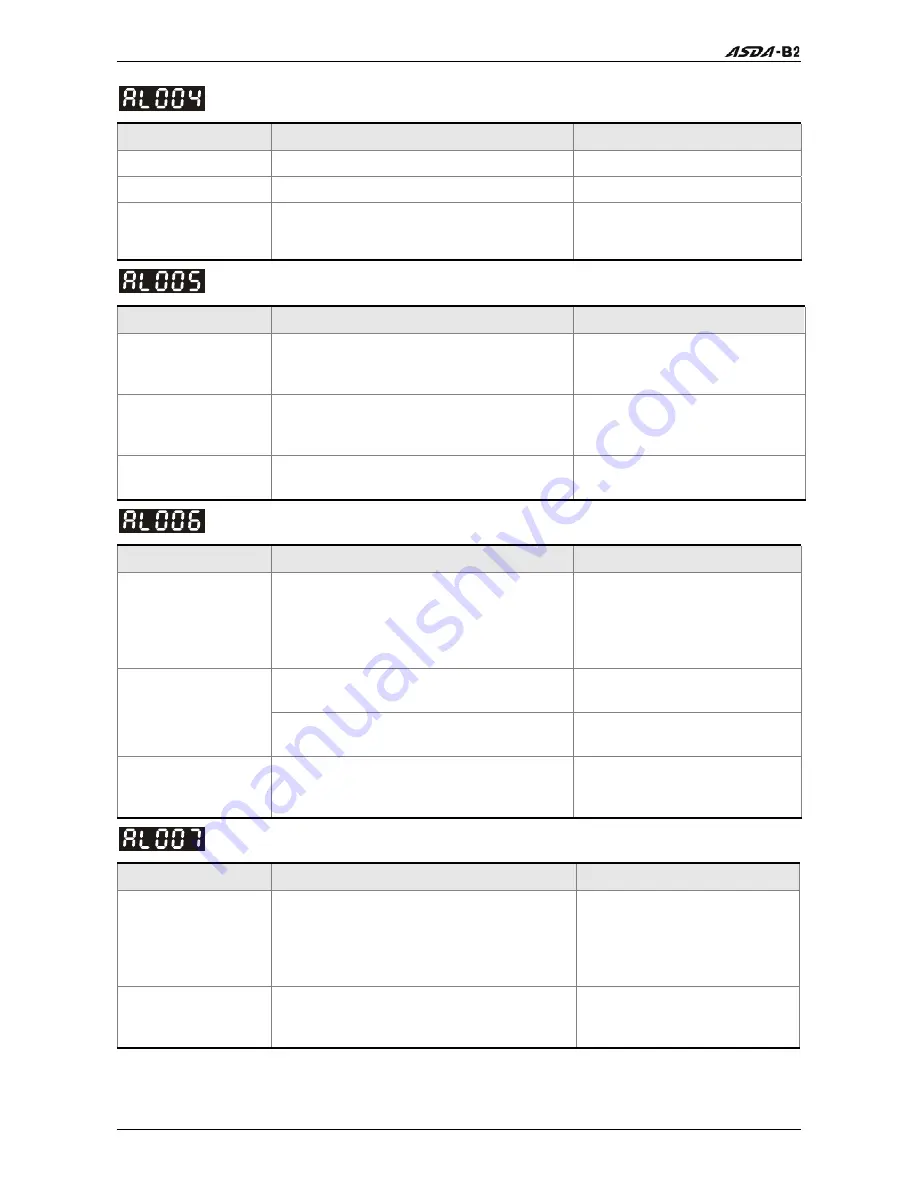

: Motor error

Potential Cause

Checking Method

Corrective Actions

Encoder is damage. Check Encoder for the damage.

Repair or replace the motor.

Encoder is loose.

Examine the Encoder connector.

Install the motor again.

The type of the

servo motor is

incorrect.

Check if the servo drive and servo motor

are not correctly matched for size (power

rating).

Replace the motor.

: Regeneration error

Potential Cause

Checking Method

Corrective Actions

Regenerative

resistor is not

connected.

Check the wiring connection of

regenerative resistor.

Reconnect regenerative

resistor.

Regenerative switch

transistor fault

Check if regenerative switch transistor is

short-circuited.

Please contact your distributor

for assistance or contact with

Delta.

Parameter setting is

in error

Confirm the parameter setting and

specifications of regenerative resistor.

Correctly reset parameter

again.

: Overload

Potential Cause

Checking Method

Corrective Actions

The drive has

exceeded its rated

load during

continuous

operation.

Check if the drive is overloaded.

Increase motor capacity or

reduce load.

Check if there is mechanical vibration

Adjust gain value of control

circuit.

Control system

parameter setting is

incorrect.

Accel/Decel time setting is too fast.

Decrease Accel/Decel time

setting.

The wiring of drive

and encoder is in

error.

Check the wiring of U, V, W and encoder. Ensure all wiring is correct.

: Overspeed

Potential Cause

Checking Method

Corrective Actions

Speed input

command is not

stable (too much

fluctuation).

Use signal detector to detect if input

signal is abnormal.

Ensure that input command

frequency is stable (not

fluctuate too much) and

activate filter function (P1-06,

P1-07 and P1-08).

Over-speed

parameter setting is

defective.

Check if over-speed parameter setting

value is too low.

Correctly set over-speed

parameter setting (P2-34).

Содержание ASD-B2-0121-B

Страница 1: ......

Страница 13: ...Table of Contents xii Revision June 2010 This page intentionally left blank...

Страница 17: ...Chapter 1 Unpacking Check and Model Explanation 1 4 Revision June 2010 ECMA Series Servo Motor...

Страница 19: ...Chapter 1 Unpacking Check and Model Explanation 1 6 Revision June 2010 1 4 Servo Drive Features...

Страница 21: ...Chapter 1 Unpacking Check and Model Explanation 1 8 Revision June 2010 This page intentionally left blank...

Страница 25: ...Chapter 2 Installation and Storage 2 4 Revision June 2010 Minimum Clearances Side by Side Installation...

Страница 43: ...Chapter 3 Connections and Wiring 3 6 Revision June 2010 Figure 3 3 Three Phase Power Supply all models...

Страница 72: ...Chapter 3 Connections and Wiring Revision June 2010 3 35 3 5 2 Connection between PC and Connector CN3...

Страница 87: ...Chapter 4 Display and Operation 4 12 Revision June 2010 This page intentionally left blank...

Страница 100: ...Chapter 5 Trial Run and Tuning Procedure Revision June 2010 5 13 5 5 2 Load Inertia Estimation Flowchart...

Страница 131: ...Chapter 6 Control Modes of Operation 6 22 Revision June 2010 Time Domain...

Страница 153: ...Chapter 6 Control Modes of Operation 6 44 Revision June 2010 This page intentionally left blank...

Страница 267: ...Chapter 8 MODBUS Communications 8 18 Revision June 2010 This page intentionally left blank...

Страница 271: ...Chapter 9 Maintenance and Inspection 9 4 Revision June 2010 This page intentionally left blank...

Страница 291: ...Chapter 11 Specifications 11 8 Revision June 2010 11 3 Servo Motor Speed Torque Curves...