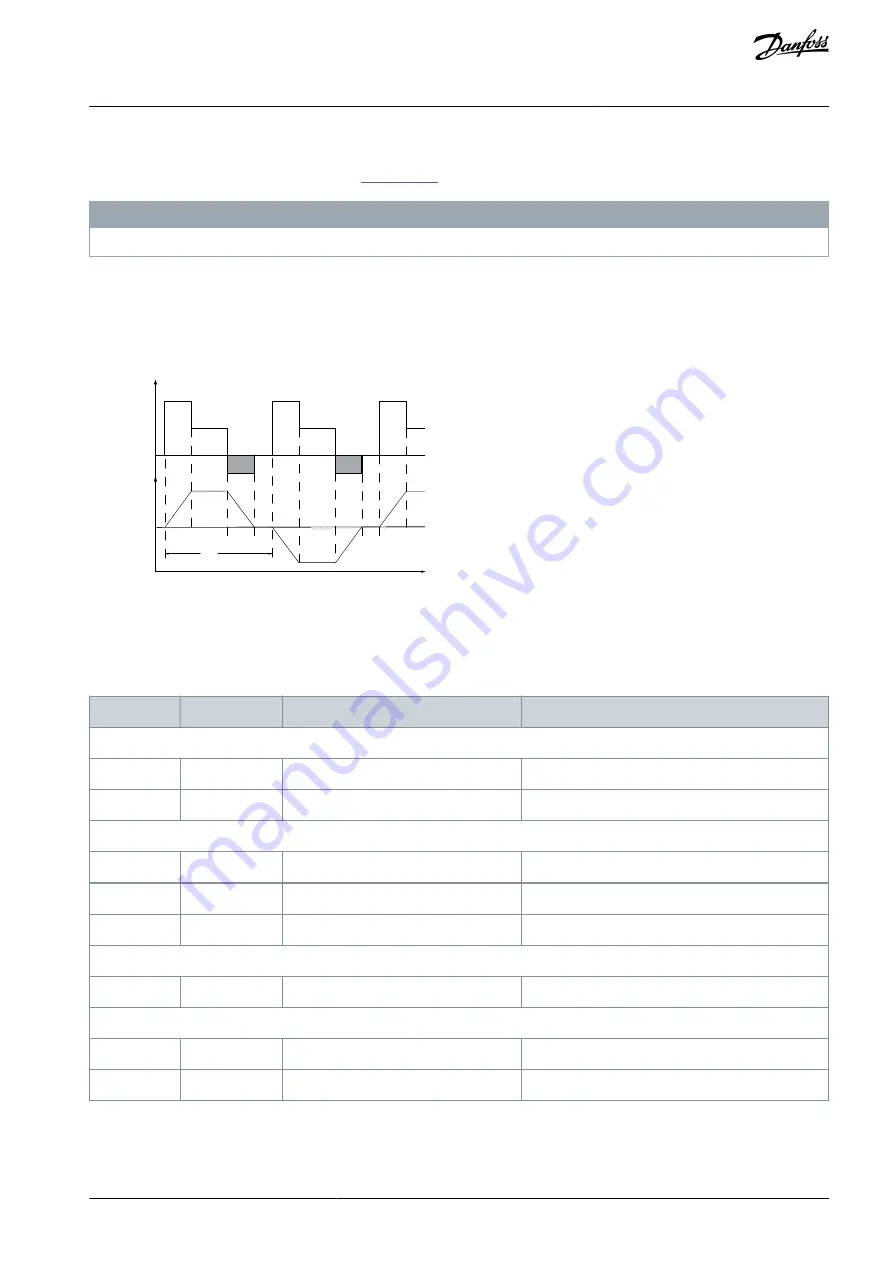

If the amount of kinetic energy transferred to the resistor in each braking period is not known, the average power can be calculated

based on the cycle time and braking time, also called intermittent duty cycle. The resistor intermittent duty cycle is an indication of

the duty cycle at which the resistor is active. See

for a typical braking cycle.

N O T I C E

Motor suppliers often use S5 when stating the allowed load, which is an expression of intermittent duty cycle.

The intermittent duty cycle for the resistor is calculated as follows:

Duty cycle=t

b

/T

T=cycle time in s.

t

b

is the braking time in s (of the cycle time).

T

ta

tc

tb

to

ta

tc

tb

to

ta

e3

0b

a1

67

.1

0

Load

Time

Speed

Illustration 74: Dynamic Braking Cycle Time

Brake resistors have a duty cycle of 5%, 10%, and 40%. If a 10% duty cycle is applied, the brake resistors are able to absorb brake

power for 10% of the cycle time. The remaining 90% of the cycle time is spent on dissipating excess heat.

Table 87: Braking at High Overload Torque Level

Cycle time (s)

Braking duty cycle at 100% torque

Braking duty cycle at overtorque (150/160%)

200–240 V

PK25–P11K

120

Continuous

40%

P15K–P37K

300

10%

10%

380–500 V

PK37–P75K

120

Continuous

40%

P90K–P160

600

Continuous

10%

P200–P800

600

40%

10%

525–600 V

PK75–P75K

120

Continuous

40%

525–690 V

P37K–400

600

40%

10%

P500–P560

600

40%

(1)

10%

(2)

AJ300847815559en-000101 / 130R0337 | 139

Danfoss A/S © 2020.09

Electrical Installation

Considerations

VLT® AQUA Drive FC 202

Design Guide