Chapter 3 — Waterside Care and Requirements

Part No. 750-184

3-9

y o u r l o c a l C l e a v e r- B r o o k s a u t h o r i z e d r e p r e s e n t a t i v e f o r

recom menda ti ons , clea ni ng compounds, and application

procedures.

2. PRESSURE VESSEL

The waterside of the pressure vessel must be kept clean from

grease, sludge, and foreign material. Such deposits, if present, will

shorten the life of the pressure vessel, will interfere with efficient

operation and functioning of control of safety devices, and quite

possibly cause unnecessary and expensive re-work, repairs, and

down-time.

The installation and operating conditions that the boiler will be

subjected to should be considered and cleaning of the waterside of

the pressure vessel should be provided during the course of initial

start-up.

The pressure vessel and the steam and return lines or hot water

piping represent, in effect, a closed system. Although the steam and

return (condensate) lines or the hot water piping system may have

been previously cleaned, it is possible that:

(1) Cleaning has been inadequate.

(2) Partial or total old system is involved.

(3) Conditions may prevent adequate cleaning of piping.

The pressure vessel waterside should be inspected on a periodic

basis. An inspection will reveal true internal conditions and serve as

a check against conditions indicated by chemical analysis of the

boiler water. Inspection should be made three months after initial

starting and at regular 6-, 9-, or 12-month intervals thereafter. The

frequency of further periodic inspections will depend upon the

internal conditions found.

If any unwanted conditions are observed, contact your local

Cleaver-Brooks authorized representative for recommendations.

Any sludge, mud or sediment found will need to be flushed out. If

excessive mud of sludge is noticed during the blowdown the

scheduling or frequency of blowdown may need to be revised. The

need for periodic draining or washout will also be indicated.

Any oil or grease present on the heating surfaces should be removed

promptly by a boil-out with an alkaline detergent solution.

Note: Temperature of initial fill of water for hydrostatic tests, boil-

out, or for normal operation should be as stated in the ASME

Boiler Code.

E. BOIL-OUT OF A NEW UNIT

The internal surfaces of a newly installed boiler may have oil, grease

or other protective coatings used in manufacturing. Such coatings

must be removed because they lower the heat transfer rate and

could cause over-heating of a tube. Before boiling out procedures

Содержание CB Ohio Special 100 HP

Страница 2: ...ii ...

Страница 8: ...viii ...

Страница 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Страница 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Страница 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Страница 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Страница 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Страница 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Страница 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Страница 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Страница 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Страница 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Страница 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Страница 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Страница 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Страница 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Страница 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Страница 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Страница 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Страница 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Страница 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

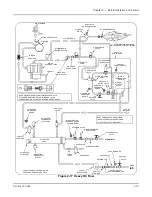

Страница 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Страница 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Страница 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Страница 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Страница 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Страница 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Страница 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Страница 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Страница 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Страница 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Страница 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Страница 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Страница 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Страница 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Страница 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Страница 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...