Chapter 3 — Waterside Care and Requirements

Part No. 750-184

3-3

A temperature of 170

°

F is also recommended in order to provide a

sufficient “temperature head” when No. 6 fuel oil is to be heated to

the proper atomizing temperature by the boiler water in a safety-

type oil preheater. (The electric preheater on the boiler must provide

additional heat to the oil if boiler water temperature is not

maintained above 200

°

F.)

Note: If the operating water temperature going to the system must

be lower than 170

°

F, the operating boiler water temperature

should be a minimum of 170

°

F (200

°

F if used to preheat No.

6 oil) and mixing valves should be used to avoid damage to

the equipment.

Rapid Replacement of Boiler Water -

The system layout and

controls should be arranged to prevent the possibility of pumping

large quantities of cold water into a hot boiler, which will cause

shock or thermal stresses. Water temperature in a boiler of 200

°

F

or 240

°

F cannot be completely replaced with 80

°

F water in a few

minutes time without causing thermal stress. The same fact applies

to periods of normal operation, as well as during initial start-up.

Note: The circulating pumps should be interlocked with the burner

so that the burner cannot operate unless the circulating pump

is running in order to avoid damage to the equipment.

W h e n i n d i v i d u a l z o n e c i r c u l a t i n g p u m p s a r e u s e d , i t i s

recommended that they be kept running-even though the heat users

do not require hot water. The relief device or by-pass valve will thus

allow continuous circulation through the boiler and can help prevent

rapid replacement of boiler water with cold zone water.

Continuous Flow Through the Boiler -

The system should be piped

and the controls arranged to allow water circulation through the

boiler under all operating conditions. The operation of three-way

valves and system controls should be checked to be sure that the

boiler will not be by-passed. Constant circulation through the boiler

eliminates the possibility of stratification within the unit and results

in more even water temperatures to the system.

A rule of thumb of 3/4 to 1 gpm per boiler horsepower can be used

to determine the minimum continuous flow rate through the boiler

under all operating conditions. The operator should determine that

a flow of water exists through the boiler before initial firing or refiring

after boiler has been drained.

Water Circulation

Table 3-1 shows the maximum gpm circulation rate of boiler water

in relation to full boiler output and system temperature drop.

Multiple Boiler Installations -

When multiple boilers are used, care

must be taken to ensure adequate or proportional flow through the

boilers. Proportional flow can best be accomplished by use of

balancing valves and gauges in the supply line from each boiler. If

balancing valves or orifice plates are used, a significant pressure

drop (e.g., 3-5 psi) must be taken across the balancing device to

accomplish the purpose.

Содержание CB Ohio Special 100 HP

Страница 2: ...ii ...

Страница 8: ...viii ...

Страница 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Страница 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Страница 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Страница 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Страница 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Страница 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Страница 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Страница 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Страница 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Страница 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Страница 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Страница 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Страница 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Страница 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Страница 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Страница 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Страница 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Страница 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Страница 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

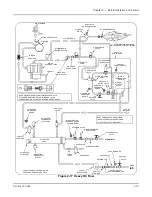

Страница 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Страница 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Страница 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Страница 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Страница 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Страница 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Страница 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Страница 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Страница 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Страница 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Страница 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Страница 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Страница 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Страница 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Страница 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Страница 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...