Chapter 6 — Adjustment Procedures

6-4

Part No. 750-184

Burners). In this position, fuel delivery is at low fire rate. Tighten the

set screws to secure the cams on the jackshaft.

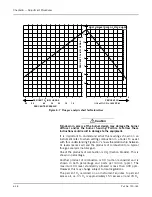

Refer to Figure 6-2. The stop screw in the rotary air damper limits

damper travel at both closed (low fire) and fully opened (high fire)

positions. The screw is provided so that it is possible to tell, even

with the burner is in place, whether the damper rotor is in fully

opened or closed position. Rotating the damper clockwise to the

s t o p s c r e w o p e n s t h e d a m p e r. R o t a t i n g t h e d a m p e r

counterclockwise to the stop screw closes the damper. Normally,

the rate of flow of air through the damper with the rotor in low fire

position is about one-third of maximum for a standard burner.

The amount of angular movement controlling the rate of air flow is

determined by the location of the ends of the rotary air damper rod

in both the jack shaft arm and the air damper arm.When the air

damper is in low fire position, the jackshaft arm should be at 45

°

and the rotar y air damper arm should be at an an gle of

approximately 60

°

below the horizontal (Figure 6-1). This will

ensure that the angular movement of the damper starts slowly,

increasing in rate as the high fire position is approached.

Prior to initially firing a boiler it is advisable to check for free

movement of the linkage. The damper motor must be allowed to

complete its full stroke and the damper must move freely from low

to high fire position. Adjustment of linkage connected to a gas

butterfly valve is described in Section Q of Chapter 6.

C. MODULATING MOTOR

The modulating motor has a 90

°

shaft rotation. The motor

manufacturer also provides a 160

°

stroke model for other

applications.

If a replacement is obtained from someone other than

a Cleaver-Brooks Service or Parts representative, it may have an

incorrect stroke. To prevent damage, determine the 90

°

stroke

prior to installing a replacement.

The stroke may be determined by powering the motor and

connecting terminals R-B to actually determine the stroke as motor

drives to an open position.

D. MODULATING MOTOR SWITCHES - LOW FIRE AND

HIGH FIRE

The modulating motor contains either one or two internal switches

depending upon application. The microswitches are actuated by

adjustable cams attached to the motor shaft.

Note: If the boiler is equipped with the CB-Hawk ICS, there are

n o en d s w i t ch e s. D o n ot at t em p t t o a dj u s t t he

Modulating Motor if the unit is equipped with the CB-

Hawk ICS

Factory replacement motors have the cams preset. The low fire start

switch is set to make the red and yellow leads at approximately 8

°

on motor closing. The high fire purge air proving switch (located in

Figure 6-2

JACK SHAFT

ROTARY AIR

DAMPER ARM

ROTARY AIR

DAMPER

STOP SCREW

DIFFUSER PLATE

DAMPER ARM

Figure 6-3

1.

ADJUST

THE

LINKAGE

TOWARD

T H E

D R I V E

S H A F T

F O R

L E S S

MOVEMENT

.

2.

ADJUST

AWAY

FROM

THE

DRIVE

S H A F T

F O R

M O R E

L I N K A G E

MOVEMENT

.

1

2

Содержание CB Ohio Special 100 HP

Страница 2: ...ii ...

Страница 8: ...viii ...

Страница 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Страница 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Страница 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Страница 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Страница 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Страница 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Страница 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Страница 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Страница 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Страница 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Страница 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Страница 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Страница 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Страница 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Страница 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Страница 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Страница 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Страница 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Страница 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

Страница 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Страница 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Страница 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Страница 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Страница 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Страница 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Страница 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Страница 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Страница 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Страница 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Страница 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Страница 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Страница 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Страница 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Страница 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Страница 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...