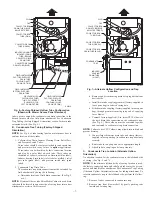

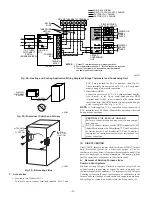

DOWNFLOW AND HORIZONTAL FURNACES

The return-air duct must be connected to return-air opening

provided. DO NOT cut into casing sides or back to attach any

portion of return-air duct. Bypass humidifier connections should

be made at ductwork or coil casing sides exterior to furnace.

V.

FILTER ARRANGEMENT

WARNING:

FIRE, CARBON MONOXIDE AND

POISONING HAZARD

Failure to follow this warning could result in intermittent

unit operation or performance satisfaction.

Never operate unit without a filter or with filter access

door removed.

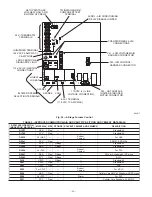

The air filter arrangement will vary due to application, furnace

orientation, and filter type. The filter may be installed in an

external Filter/Media cabinet (if provided) or the furnace blower

compartment. Factory supplied washable filters are shipped in the

blower compartment.

If a factory-supplied external Filter/Media cabinet is provided,

instructions for its application, assembly, and installation are

packaged with the cabinet. The Filter/Media cabinet can be used

with the factory-supplied washable filter or a factory-specified

high-efficiency disposable filter (see cabinet instructions).

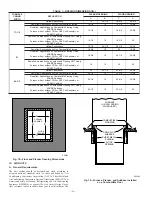

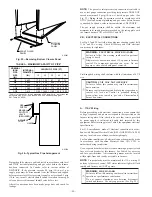

If installing the filter in the furnace blower compartment, deter-

mine location for filter and relocate filter retaining wire if

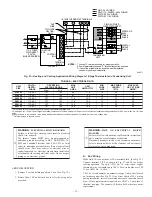

necessary. See Table 2 to determine correct filter size for desired

filter location. Table 2 indicates filter size, location, and quantity

shipped with this furnace. See Fig. 2 for location and size of

bottom and side return-air openings.

CAUTION:

CUT HAZARD

Failure to follow this caution may result in minor

personal injury.

Use care when cutting support rods in filters to protect

against flying pieces and sharp rod ends. Wear safety

glasses, gloves, and appropriate protective clothing.

CAUTION:

UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent

unit operation or performance satisfaction.

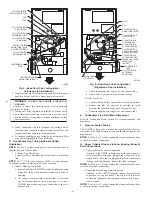

For airflow requirements above 1800 CFM, see Air

Delivery table in Product Data literature for specific use

of single side inlets. The use of both side inlets, a

combination of 1 side and the bottom, or the bottom only

will ensure adequate return air openings for airflow

requirements above 1800 CFM.

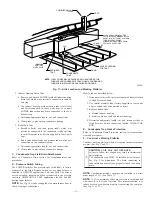

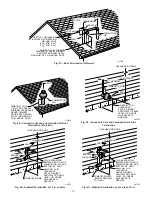

Fig. 22—Crawlspace Horizontal Application

A93304

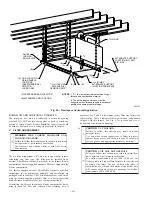

NOTES:

ANGLE

IRON OR

EQUIVALENT

(B)

(A) ROD LOCATION

USING DIMPLE

LOCATORS

(SEE DIMENSIONAL

DWG FOR

LOCATIONS)

13

/

16

-IN. MAX

ALTERNATE SUPPORT

LOCATION FROM BACK

ALTERNATE SUPPORT

LOCATION 4-IN. MIN

8-IN. MAX

3

⁄

8

-IN. ROD

(A)

(B)

(A)

(B)

(B)

(A)

1. A 1 In. clearance minimum between top of

furnace and combustible material.

2. The entire length of furnace must be

supported when furnace is used in horizontal

position to ensure proper drainage.

(A) PREFERRED ROD LOCATION

(B) ALTERNATE ROD LOCATION

DRAIN

5

3

⁄

4

″

3

/

8

-IN. HEX NUT

& WASHER (4)

REQD PER ROD

—18—

→

Содержание CONDENSING GAS FURNACE 352MAV

Страница 51: ...51...