SAFETY CONSIDERATIONS

CAUTION:

FURNACE RELIABILITY HAZARD

Improper installation or misapplication of furnace may

require excessive servicing or cause premature compo-

nent failure.

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate,

air temperature rise, unit leveling, and unit sizing.

WARNING:

FIRE,

EXPLOSION,

ELECTRICAL

SHOCK AND CARBON MONOXIDE POISONING

HAZARD

Failure to follow this warning could result in electrical

shock, fire, personal injury, or death.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poison-

ing, explosion, fire, electrical shock, or other conditions

which may cause personal injury or property damage.

Consult a qualified installer, service agency, local gas

supplier, or your distributor or branch for information or

assistance. The qualified installer or agency must use

only factory-authorized and listed kits or accessories

when modifying this product.

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified

personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in literature, on tags, and

on labels attached to or shipped with unit and other safety

precautions that may apply.

These instructions cover the minimum requirements and conform

to existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residen-

tial construction practices. We require these instructions as a

minimum for a safe installation.

Wear safety glasses and work gloves.

CAUTION:

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing and gloves when

handling parts.

Recognize safety information. This is the safety-alert symbol

.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words: DANGER, WARNING and CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

INTRODUCTION

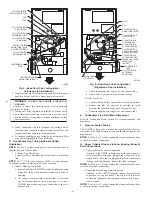

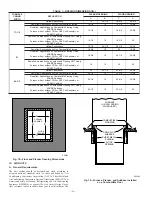

The model 352MAV, 2-Stage, 4-way multipoise, Gas-Fired, Cat-

egory IV, direct vent condensing furnace is available in model

sizes ranging in input capacities (high-stage) of 60,000 to 120,000

Btuh. This furnace is CSA (formerly AGA and CGA) design-

certified for natural and propane gases and for installation in

alcoves, attics, basements, closets, utility rooms, crawlspaces, and

garages. This furnace is factory-shipped for use with natural gas. A

CSA listed gas conversion kit is required to convert furnace for use

with propane gas.

This furnace shall not be installed directly on carpeting, tile, or

any other combustible material other than wood flooring. For

downflow installations, a factory accessory floor base must be

used when installed on combustible materials and wood flooring.

Special base is not required when this furnace is installed on the

manufacturer’s coil assembly or when the manufacturer’s coil box

is used. The design of the 352MAV furnace is not CSA certified

for installation in mobile homes, recreational vehicles, or outdoors.

This furnace is suitable for installation in a structure built on site

or a manufactured building completed at final site.

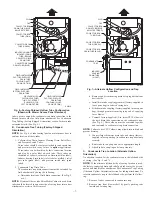

This furnace is designed for minimum continuous return-air

temperature of 60°F db or intermittent operation down to 55°F db

such as when used with a night setback thermostat. Return-air

temperature must not exceed 80°F db. Failure to follow these

return air limits may affect reliability of heat exchangers, motors

and controls. (See Fig. 4.)

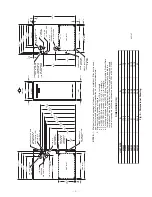

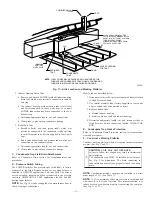

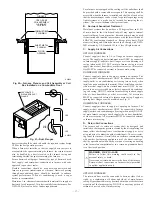

This furnace is shipped with the drain and pressure tubes con-

nected for UPFLOW applications. Minor modifications are re-

quired when used in DOWNFLOW, HORIZONTAL RIGHT,

or HORIZONTAL LEFT (supply-air discharge direction) appli-

cations as shown in Fig. 1. See details in Applications section.

•

Install this furnace in a location and position as specified in

LOCATION and INSTALLATION sections of these instruc-

tions.

•

Combustion products must be discharged outdoors. Connect

this furnace to an approved vent system only, as specified in the

Combustion Air and Vent piping sections of these instructions.

•

Never test for gas leaks with an open flame. Use a commer-

cially available soap solution made specifically for the detec-

tion of leaks to check all connections, as specified in the GAS

PIPING section of these instructions.

Fig. 1—Multipoise Orientations

A93041

UPFLOW

DOWNFLOW

HORIZONTAL

LEFT

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

HORIZONTAL

RIGHT

—2—

→

→

→

Содержание CONDENSING GAS FURNACE 352MAV

Страница 51: ...51...