5. Disassemble loose pipe fittings. Clean and cement using

same procedures as used for system piping.

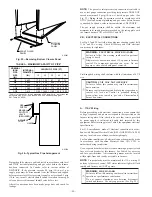

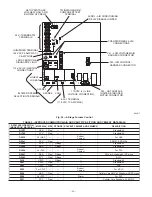

6. Check required dimensions as shown in Fig. 38 or 39.

E.

Multiventing and Vent Terminations

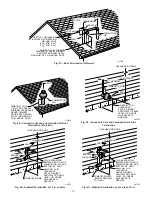

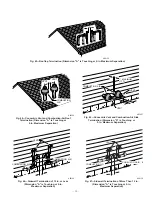

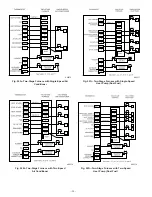

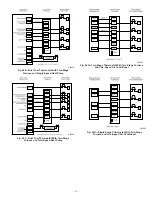

When 2 or more 352MAV furnaces are vented near each other,

each furnace must be individually vented. NEVER common vent

or breach vent 352MAV furnaces. When 2 or more 352MAV

furnaces are vented near each other, 2 vent terminations may be

installed as shown in Fig. 43, 44, 45, 46, or 47 but the next vent

termination must be at least 36 in. away from first 2 terminations.

It is important that vent terminations be made as shown to avoid

recirculation of flue gases. Dimension A in Fig. 43, 44, 45, 46, and

47 represents distance between pipes or rain shields, as touching or

2-in. maximum separation.

X.

CONDENSATE DRAIN

CAUTION:

UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent

unit operation.

Unit must not be installed, operated, and then turned off

and left in an unoccupied structure during cold weather

when temperature drops to 32°F and below unless drain

trap and drain line have adequate freeze protection. See

Service and Maintenance Instructions for winterizing

procedure. (See Fig. 42.)

A.

General

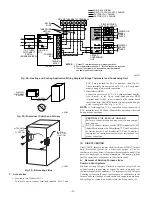

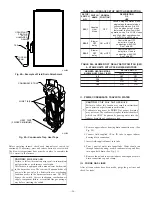

Condensate trap is shipped installed in the blower shelf and factory

connected for UPFLOW application. Condensate trap must be

RELOCATED for use in DOWNFLOW and HORIZONTAL

applications.

Condensate trap MUST be used for all applications.

An external trap is not required when connecting the field drain to

this condensate trap.

The field drain connection (condensate trap or drain tube coupling)

is sized for l/2-in. CPVC, 1/2-in. PVC, or 5/8-in. ID tube

connection.

Drain pipe and fittings must conform to ANSI standards and

ASTM D1785, D2466 or D2846. CPVC or PVC cement must

conform to ASTM D2564 or F493. Primer must conform to ASTM

F656. In Canada, use CSA or ULC listed schedule 40 CPVC or

PVC drain pipe, fittings, and cement.

When a condensate pump is required, select a pump which is

approved for condensing furnace applications. To avoid conden-

sate spillage, select a pump with an overflow switch.

Furnace condensate is mildly acidic, typically in the pH range of

3.2 to 4.5. Due to corrosive nature of this condensate, a condensate

pH neutralizing filter may be desired. Check with local authorities

to determine if a pH neutralizer is required.

B.

Application

The furnace, A/C, and humidifier drains may be combined and

drained together. The A/C drain must have an external, field-

supplied trap prior to the furnace drain connection. All drain

connections (furnace, A/C, or humidifier) must be terminated into

an open or vented drain as close to the respective equipment as

possible to prevent siphoning of the equipment’s drain.

See Fig. 48 for example of possible field drain attachment using

1/2-in. CPVC or PVC tee for vent and A/C or humidifier drain

connection.

Outdoor draining of the furnace is permissible if allowed by local

codes. Caution should be taken when freezing ambient may freeze

drain pipe and prohibit draining.

WARNING:

PERSONAL INJURY HAZARD

Failure to follow this warning could result in property

damage and personal injury or death.

Caution should be taken to prevent draining where

slippery conditions may cause personal injuries. Exces-

sive condensate draining may cause saturated soil condi-

tions which may result in damage to plants.

C.

Condensate Drain Protection

Freezing condensate left in condensate trap and drain line may

cause cracks, and possible water damage may occur. If freeze

protection is required, use condensate freeze protection accessory

or equivalent 3 to 6 watt per ft at 120-v and 40°F self-regulating,

shielded, and waterproof heat tape. See Installation Instructions

supplied with accessory or heat tape manufacturer’s recommenda-

tions.

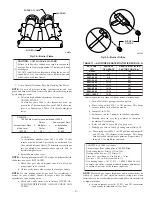

1. Fold heat tape in half and wrap on itself 3 times.

2. Locate heat tape between sides of condensate trap back.

(See Fig. 49.)

3. Use wire ties to secure heat tape in place. Wire ties can be

positioned in notches of condensate trap sides. (See Fig.

49.)

4. Wrap field drain pipe with remaining heat tape, approxi-

mately 1 wrap per ft.

5. When using field-supplied heat tape, follow heat tape

manufacturer’s instructions for all other installation guide-

lines.

START-UP ADJUSTMENT AND SAFETY CHECK

CAUTION:

UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent

unit operation.

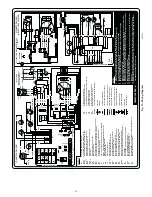

Furnace control must be grounded for proper operation,

or control will lock out. Control is grounded through

green/yellow wire connected to gas valve C-terminal and

burner box screw.

I.

GENERAL

The furnace must have a 115-v power supply properly connected

and grounded. Proper polarity must be maintained for correct

operation.

NOTE:

Proper polarity must be maintained for 115-v wiring. If

polarity is incorrect, control status indicator light will flash rapidly

and the furnace will not operate.

Natural gas service pressure must not exceed 0.5 psig (14-in. wc),

and no less than 0.16 psig (4.5-in. wc).

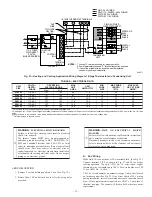

Thermostat wire connections at R and W/W1 are the minimum

required for gas heating operation. W2 must be connected for

2-stage heating thermostats. C

OM

, Y/Y2, and G are required for

cooling, heat pumps, and some clock thermostats. These must be

made at the 24-v terminal block on the control. (See Fig. 32.)

This furnace can be installed with either a single-stage heating or

a 2-stage heating thermostat.

For single-stage thermostats, connect thermostat W to W/W1 at

furnace control terminal block. (See Fig. 27.) For single-stage

thermostats, the control will determine, based on length of previ-

ous heating on and off cycles, when to operate in low- and high-

gas heat for optimum comfort. Setup switch-1 (SW-1) must be in

the factory-shipped OFF position. See Fig. 31 and Table 9A and

9B for setup switch information.

If a 2-stage heating thermostat is to be used, move SW-1 to ON

position at end of furnace installation. This overrides built-in

control process for selecting high and low fire and allows the

2-stage thermostat to select gas heating modes. The W2 from

thermostat must be connected to W2 on control terminal block.

(See Fig. 28 and Fig. 52A-G.)

—34—

Содержание CONDENSING GAS FURNACE 352MAV

Страница 51: ...51...