WARNING:

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in electrical

shock, fire, or death.

The furnace casing MUST have an uninterrupted or

unbroken ground according to NEC ANSI/NFPA 70-

2002 and Canadian Electrical Code CSA C22.1 or local

codes to minimize personal injury if an electrical fault

should occur. This may consist of electrical wire or

conduit approved for electrical ground when installed in

accordance with existing electrical codes. Do not use gas

piping as an electrical ground.

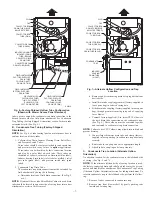

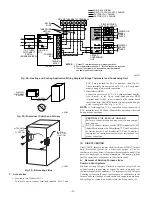

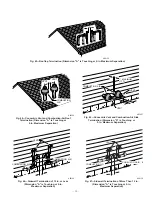

J-BOX RELOCATION

1. Remove 2 screws holding auxiliary J-box. (See Fig. 30.)

2. Rotate J-box 180° and attach box to left side, using holes

provided.

WARNING:

FIRE

OR

ELECTRICAL

SHOCK

HAZARD

Failure to follow this warning could result in intermittent

unit operation or performance satisfaction.

If manual disconnect switch is to be mounted on furnace,

select a location where a drill or fastener will not contact

electrical or gas components.

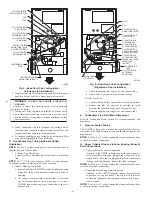

B.

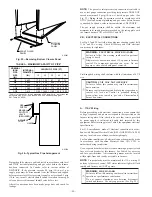

24-V Wiring

Make field 24-v connections at 24-v terminal block. (See Fig. 32.)

Connect terminal Y/Y2 as shown in Fig. 27 and 28 for proper

cooling operation. Use only AWG No. 18, color-coded, copper

thermostat wire for lengths up to 100 ft. For wire lengths over 100

ft, use AWG No. 16 wire.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on furnace control (See Fig. 32.) Any direct shorts of 24-v wiring

during installation, service, or maintenance could cause this fuse to

blow. If fuse replacement is required, use ONLY a 3-amp fuse of

identical size/type. The control will flash code 24 when fuse needs

replacement.

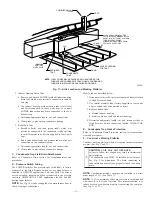

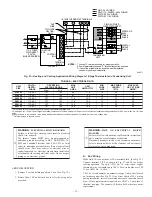

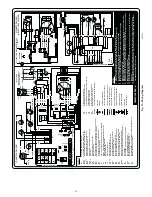

Fig. 27—Heating and Cooling Application Wiring Diagram 1-Stage Thermostat and Condensing Unit

A99071

115-V FUSED

DISCONNECT

SWITCH

(WHEN REQUIRED)

JUNCTION

BOX

CONTROL

BOX

24-V

TERMINAL

BLOCK

TWO-WIRE

HEATING-

ONLY

FIVE

WIRE

1-STAGE THERMOSTAT TERMINALS

FIELD-SUPPLIED

FUSED DISCONNECT

CONDENSING

UNIT

FURNACE

COM

R

W

Y

R

G

C

GND

GND

GND

GND

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

WHT

BLK

WHT

BLK

W/W1

W2

Y/Y2

G

NOTES:

1. Connect Y-terminal as shown for proper operation.

2. Some thermostats require a "C" terminal connection as shown.

3. If any of the original wire, as supplied, must be replaced,

use same type or equivalent wire.

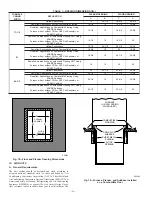

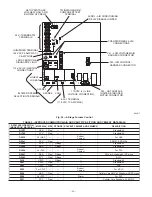

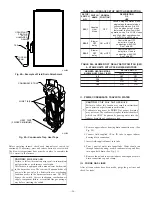

TABLE 4—ELECTRICAL DATA

UNIT

SIZE

VOLTS—

HERTZ—

PHASE

OPERATING

VOLTAGE RANGE

MAX

UNIT

AMPS

UNIT

AMPACITY†

MIN

WIRE

SIZE

MAX WIRE

LENGTH

(FT)‡

MAX FUSE

OR CKT BKR

AMPS**

Max*

Min*

036060

115-60-1

127

104

8.4

11.3

14

33

15

036080

115-60-1

127

104

8.1

10.8

14

34

15

048080

115-60-1

127

104

11.6

15.3

12

37

20

048100

115-60-1

127

104

11.6

15.4

12

37

20

060100

115-60-1

127

104

13.3

17.5

12

33

20

060120

115-60-1

127

104

12.9

16.8

12

34

20

* Permissible limits of voltage range at which unit will operate satisfactorily.

† Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier, etc.) full load

amps.

‡ Length shown is a measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

** Time-delay type is recommended.

—21—

Содержание CONDENSING GAS FURNACE 352MAV

Страница 51: ...51...