RS1500000 Rev. 0

42

Service Information

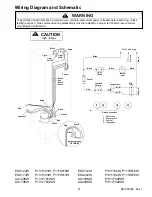

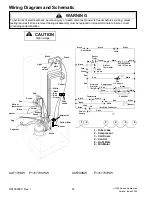

To avoid risk of electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service unless test procedures require power to be connected. When removing any wiring from

terminals, replace on the same terminals. Ensure all ground wires are connected before certifying unit as repaired

and/or operational.

WARNING

!

Evacuation and Charging Procedures

!

WARNING

Sealed system on these freezer models use R134a refrigerant. If sealed system work on these models is required,

used approved equipment and follow service procedures. See

HFC134a Service Information

section of this

manual or Service Letter F842 for service procedures.

CAUTION

!

To minimize contamination, exercise extreme care when servicing HFC134a sealed systems.

No trace of other refrigerants is allowed in HFC134a systems. Chlorinated molecules in other refrigerants

such as CFC12, etc. lead to capillary tube plugging.

Ester oil is used in HFC134a systems. Do not use mineral oil. HFC134a and mineral oils cannot be mixed. If

mineral oils are used in HFC134a systems, lubricant would not return to compressor and would cause early

compressor failure. If significant amount of oil has been lost from compressor, replace oil rather than adding oil.

Low-side leak repairs of HFC134a systems are different from those of CFC-12 systems. Ester oils used in

HFC134a systems are so hydroscopic that by the time an inadequate system performance is detected, oil will

be saturated with moisture.

CFC12 has much higher tolerance to system processing materials, such as drawing compounds, rust inhibitors,

and cleaning compounds, than HFC134a. Such materials are not soluble in HFC134a systems. If materials

were to be washed from system surfaces by ester oils, they could accumulate and eventually plug capillary

tube.

Care must be taken to minimize moisture from entering HFC134a system. Do not leave compressor or system

open to atmosphere for more than 10 minutes. Excessive moisture in HFC134a system will react with

compressor oil and generate acid.

Compressor must always be replaced when performing low side leak repair.

Drier filter must be replaced whenever seal system is opened.

Important:

Unbrazing drier filter from tubing will drive moisture from desiccant and into system, causing acids

to form. Do not unbraze filter drier from tubing. If CFC12 service drier was installed in HFC134a

system, drier could overload due to excessive moisture.

Clean, dry HFC134a compatible copper tubing must be used when replacing tubing.

Avoid system contamination by using Towerdraw E610 evaporating oil, part # R0157532, when flaring, swaging,

or cutting refrigeration tubing.