35

RS1500000 Rev. 0

Disassembly Procedures

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before following any

disassembly procedures.

WARNING

!

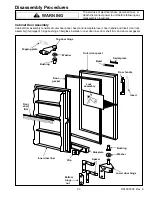

Removing Door Lock Assembly

1. Remove all inner door liner mounting screws on door

lock side, and four from the top and bottom, working

in from the lock side.

2. Pull inner door liner out far enough to reach the lock

bolt.

3. Using a screw driver pushed through foam block.

Remove screw securing lock cam. Lock cam then

can be removed.

4. Remove clip holding lock to outer door panel. Push

lock out of door panel.

5. Reassemble in reverse order.

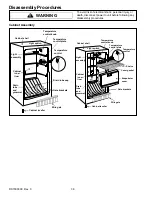

Cabinet Door Alignment

Cabinet door on each model is in correct alignment

when:

Hinge side of door is equidistant from cabinet flange at

the top and bottom.

Gasket seals smoothly and is compressed no more

than 1/16 inch (1.6 mm) along the hinge side with door

closed.

Handle side of door should be 1/16 inch (1.6 mm)

above the handle side of the cabinet (viewed from the

front). Upper hinge side corner of door should be 1/16

inch (1.6 mm) above the cabinet top.

In many cases, levelling the freezer will eliminate needed

for cabinet door adjustments. Verify freezer is level by

checking both front edges as well as both sides of the

cabinet, with a carpenters level. Adjust levellers until

cabinet is in a true vertical position.

Checking Gasket Seal

Door gasket seals effectively with its normal pull. Visual

inspection will usually reveal any point of poor seal.

Double check locations which are questionable by

closing the door on a narrow strip of paper. Any areas

that will not support the weight of the paper are

considered areas of poor gasket seal.

On areas which cannot be checked visually or with a

paper, rub blue carpenters chalk on the gasket, or

dampen the gasket, and close door several times.

Examine the cabinet flange for transfer of chalk or

dampness. Failure of the transfer indicates areas of poor

seal.

Improving Gasket Seal

In order for gasket to compress evenly around the entire

door, it must make contact at the top and bottom at the

same time. For this reason the door, should not toe-in or

toe-out.

To correct a toe-in or toe-out condition verify hinge side

of door is parallel to the cabinet.

1. Check cabinet levellers. Turning leveller in or out may

correct a toe-in or toe-out condition.

2. Loosen all inner door panel mounting screws along

the top, bottom, and latch side of the door.

NOTE:

Do not loosen screws along hinge side.

3. Hold the corner that toes-in stationary; push in on the

toe-out corner until door is lined up parallel with the

cabinet. Tighten a few screws on latch side to hold

door in position.

4. Open and close door several times to insure proper

fit. If necessary, repeat steps 2 and 3.

5. Tighten all loosened screws until they are snug. Do

not tighten screws too much, heads may pull through

screw hole.

Hinge Adjustments

Hinge adjustments are necessary when:

Gasket is not sealing sufficiently along hinge side of

door.

Gasket is compressed more than 1/16 inch (1.6 mm)

on hinge side (causing a poor seal elsewhere around

the door).

Distance between the door and cabinet is greater at

the top than it is at the bottom, or vice versa.

Handle side of the door does not line up with cabinet

side (when viewed from the front), or upper latch side

corner is higher or lower than the cabinet top.

If one or more of these conditions exist, verify cabinet is

level and make necessary hinge adjustments as

instructed below.

Turning out the hinge side front leveller may correct a

door sag.

Oversized holes in the cabinet top permit some

sideways, or in and out adjustments of the top hinge.

Raise top hinge by placing a 1/32 inch (0.8 mm) shim

beneath it.

Lower hinge can be moved out by adding a 1/32 inch

(0.8 mm) shim between it and the cabinet.