RS1500000 Rev. 0

38

Service Information

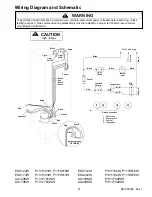

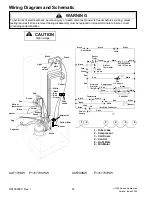

To avoid risk of electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service unless test procedures require power to be connected. When removing any wiring from

terminals, replace on the same terminals. Ensure all ground wires are connected before certifying unit as repaired

and/or operational.

WARNING

!

Checking Operating Pressures

If refrigeration system is not operating properly, check

operating pressures.

Install a piercing valve on compressor process tube and

on high side process tube.

NOTE:

Piercing valve should not be left on the tubing

after tests are complete. Remove the valve from

discharge line and repair the opening. Evacuate

and recharge the system.

When using gauges to verify operating pressures,

observe the following precautions.

1. Verify gauges are accurately calibrated. When not

connected into a system, gauge pointers should

indicate 0 pressure. If necessary, turn the

recalibrating screw on the dial until the pointer

indicates 0.

2. Verify temperature control is set to normally maintain

a 0°F (-17°C) temperature.

3. Remove all unfrozen food from the freezer.

4. Before taking final gauge readings, allow freezer to

run through several cycles with the door closed. This

will allow the temperature and pressures to stabilize.

5. Compare the final gauge readings for the model

being serviced, see the category which applies to the

readings indicated.

High Side

near normal pressure

Low Side

lower pressure (possible vacuum)

Wattage

lower than normal

Freezer shelf tubing or other low side tubing is probably

restricted (kinked or blocked with foreign particle). This

condition is usually accompanied with a frost build-up on

the low side of the restriction. High side pressures will

not unload and balance with the low side within the

prescribed seven to ten minutes after the compressor is

stopped.

High Side

low pressure

Low Side

lower pressure (possible vacuum)

Wattage

lower than normal

Indicates a leak in the high side of the system. Both

gauges will show progressively less pressure.

High Side

much higher pressure

Low Side

slightly

lower pressure

Wattage

higher than normal

Indicates a leak in the low side of the system. High side

pressures will continually increase drawing through the

leak becoming trapped in the high side tubing. Low side

gauge will show a slight pressure being drawn in through

the leak.

High Side

lower pressure

Low Side

lower pressure (possible vacuum)

Wattage

lower than normal

Indicates restriction at the entrance of the capillary tube.

High side pressures will take much longer than the

prescribed seven to ten minutes to unload and balance

with the low side after compressor has stopped.

High Side

higher pressure

Low Side

higher pressure

Wattage

higher than normal

Indicates an overcharge of refrigerant. Pressure

increasing depends on the amount of overcharge and

room temperature.

A slight overcharge may not cause trouble in 70°F (21°C)

temperatures, where as in 90°F (32°C) temperatures a

considerable rise in pressure will result.

An overcharge may also cause the suction line under the

cabinet to be frosted during the run cycle. This condition

will confirm the existence of an overcharge.

High Side

higher pressure

Low Side

near normal pressure

Wattage

higher than normal

Indicates air in the system. Resulting from a low side

leak being repaired without the system being thoroughly

evacuated and purged before recharging.

In most cases, you will find that the freezer is not as cold

as it should be, because the efficiency of the system is

greatly reduced by the presence of air.

Simply purging air from the system is not practical. The

system being undercharged due to the loss of

refrigerant. Evacuate, purge, and recharge the system