47

RS1500000 Rev. 0

Service Information

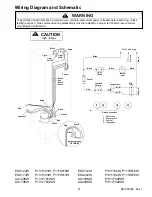

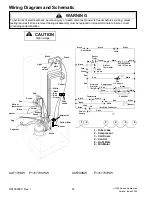

To avoid risk of electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service unless test procedures require power to be connected. When removing any wiring from

terminals, replace on the same terminals. Ensure all ground wires are connected before certifying unit as repaired

and/or operational.

WARNING

!

Dehydrating Sealed Refrigeration System

It is a misconception that moisture in a sealed refrigerant

system is harmless. Moisture in a sealed refrigerant

system, when exposed to heat generated by the

compressor and motor, reacts chemically with refrigerant

and oil in the system and forms corrosive hydrochloric

and hydrofluoric acids. These acids contribute to the

breakdown of motor winding insulation and corrosion of

compressor working parts, causing compressor failure.

In addition, sludge, a residue of the chemical reaction,

coats all surfaces in the sealed system, and will

eventually restrict refrigerant flow through the capillary

tube.

To dehydrate the sealed system:

1. Perform the leak test.

2. Capture refrigerant in system.

NOTE

: It is the responsibility of the service technician to

capture refrigerant in system for safe disposal,

before opening any refrigeration system.

3. Repair any leaks in system.

4. Evacuate system.

5. Recharge to specification with new refrigerant.

NOTE

: Do not use captured or recycled refrigerant in

Amana units. Captured or recycled refrigerant

voids any Amana and/or compressor

manufacturers warranty.

Brazing

CAUTION

!

Brazing requires high temperatures. Take all

necessary precautions to protect against personal

injury and property damage.

Satisfactory results require cleanliness, experience, and

use of proper materials and equipment.

Connections to be brazed must be properly sized, free of

rough edges, and clean.

Generally accepted brazing materials are:

Copper to copper joints

: SIL-FOS

(alloy of 15%

silver, 80% copper, and 5% phosphorous). Use

without flux. Recommended brazing temperature is

approximately 1400°F.

DO NOT USE FOR COPPER

TO STEEL CONNECTION

.

Copper to steel joints

: SILVER SOLDER

(alloy of

30% silver, 38% copper, 32% zinc).

Use with fluoride

based flux. Recommended brazing temperature is

approximately 1200°F.

Steel to steel joints

: SILVER SOLDER (see above).

Brass to copper joints

: SILVER SOLDER (see

copper to steel connections).

Brass to steel joints

: SILVER SOLDER (see copper

to steel connections).

Refrigerant Precautions

WARNING

!

To avoid personal injury do not allow refrigerant to

contact eyes or skin. Do not burn refrigerant.

CAUTION

!

Do not use refrigerant other than that shown on unit

serial number identification plate.

NOTE

: All precautionary measures recommended by

refrigerant manufacturers and suppliers apply

and should be observed.

Open Lines

During any processing of refrigeration system, never

leave lines open to the atmosphere. Open lines allow

water vapor to enter system, making proper evacuation

more difficult.