RS1500000 Rev. 0

40

Service Information

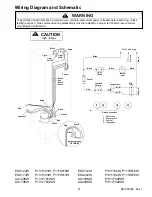

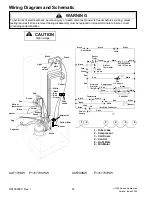

To avoid risk of electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service unless test procedures require power to be connected. When removing any wiring from

terminals, replace on the same terminals. Ensure all ground wires are connected before certifying unit as repaired

and/or operational.

WARNING

!

Refrigeration System Complaints

Common occasions for customer requesting service are

listed below with possible reasons and tests to diagnose

problem before replacements are made.

1. Cabinet temperature does not come down:

a. Refrigerant charge is low. Examine frost line at tail

end of the evaporator.

b. Compressor is inoperative (see compressor

sections).

c. Control has been turned to "OFF" position.

d. Freeze-up

2. Compressor will not start:

a. Lack of power. Verify power availability at

compressor terminals.

b. Starting relay has failed. Connecting starting relay

contacts L & S for 1 second should result in a

normal start. Replace starting relay.

c. Overload protector has failed in open position.

Replace overload.

d. One of compressor windings is open. Check

winding resistances. Resistance between CDS

and CDR should be less than 100 ohms.

e. Compressor is locked (seized). If voltage is

normal, there is no failure in the relay protector or

any connections leading to the compressor

terminals, and the amperage drawn is high.

Compressor has failed.

3. Compressor overload thermostat is operating

frequently but cabinet temperature has not risen

noticeably.

a. Voltage under 10 VAC.

b. Voltage over 127 VAC.

c. Lid is being opened frequently so compressor

"OFF" time is too short for pressure equalization.

d. Installation condition is causing compressor to run

hotter than usual (for example, lack of air

circulation around freezer shell).

e. Overload thermostat has failed.

4. Continuous running:

a. Freezer has been filled with unfrozen or warm

food.

b. Room temperature exceeds recommended

maximum.

c. Cabinet is placed near radiator or other heat

source, such as strong sunlight.

d. Temperature control is incorrectly adjusted or has

failed.

e. Refrigerant charge is low

f. Freeze-up

5. Compressor runs too long:

This is usually a statement of opinion by

customer. For a normal storage temperature at

0°F, expected running times are shown in

"Performance Data" table, see "Component

Testing" section, page 12.

Running times can vary substantially depending

on usage and conditions.

6. Freeze-up:

Moisture freezing in the sealed system is extremely

rare; however, it may be encountered when sealed

system is opened for service.

a. Moisture freeze-up is indicated by continuous

running and high cabinet temperatures. Use a

suction pressure gauge to diagnose problem. As

freezer pulls down, back pressure drops to a

vacuum. By pulling freezer plug and warming

cabinet until evaporate exceeds 0°C the ice will

melt and cause a rapid rise in pressure. This can

be duplicated any number of times.

b. Freeze-up can only be corrected by evacuating

system with a vacuum pump, and by installing a

new, oversized, high side drier.

NOTE:

Effective July 1, 1992, it is responsibility of

service technician to capture refrigerant for safe

disposal.

c. In case of freeze-ups, the unit's current draw

(amperage) will usually be low, about 70 percent

of serial plate.