37

RS1500000 Rev. 0

Service Information

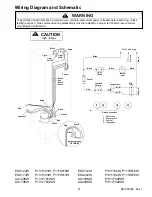

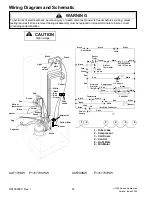

To avoid risk of electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service unless test procedures require power to be connected. When removing any wiring from

terminals, replace on the same terminals. Ensure all ground wires are connected before certifying unit as repaired

and/or operational.

WARNING

!

System Operation

If freezer is not operating properly and electrical failure is

not ruled out, refer to the electrical system and perform

the necessary electrical tests before making any test

which requires opening the system.

If there is no electrical failure and system does not

operate properly, such as long run periods or warmer

than normal compartment temperatures, the cause may

be one of the following.

Failed Compressor

A compressor which is not pumping adequately will

produce very little cooling effect. The shelf tubing may

be covered with a thin film of frost, but the temperature

will not reach control cut-off level, even with continuous

running.

Because these conditions are similar to those for a

refrigerant leak, perform leak test. If no leak is found,

install gauges and check the operating pressures. If

high side pressures are lower than those in the table in

the Specification section and low side pressures are

higher than specified, the compressor must be replaced.

Restricted Capillary Tube

The inner diameter of a capillary tube is about the same

size as the period at the end of this sentence. It doesnt

take much to restrict this area. Use care when moving or

touching the capillary tube, slight kink can cause a

restriction.

Restrictions of capillary tube may be caused by moisture

freeze-up, foreign particles lodged in the tube, or a kink.

If capillary tube is restricted, there will be noticeable lack

of frost on the refrigerated shelves or evaporator. The

compressor will operate for a short time then cycle on

the overload.

Moisture in the System

Any moisture in the system will usually freeze at the

outlet end of the capillary tube, where it enters the

evaporator coil. Preventing refrigerant from entering the

coil. This results in loss of cooling with the compressor

continuously operating. When the evaporator

temperature rises above freezing, moisture restriction

will melt and refrigerant will circulate through the system.

Freezer will operate normally until another freeze-up

occurs, which depends upon the amount of moisture in

the system.

If compressor is operating but evaporator coil or

refrigerated shelves are not refrigerated, stop the

compressor and listen for refrigerant surging through

tubing. If a gurgling sound is heard, capillary tube is not

restricted. Check for a leak or check operating

pressures.

When first opening the door no refrigerant circulating

sound is heard, but after several minutes it is noticeable,

there is probably moisture in the system which is freezing

at the capillary tube outlet. Install a new drier, evacuate,

and recharge.

If no moisture is in the system and no leaks, check for

kinked tubing. Sometimes a kink in a large tube will not

affect the system operation. Kink in the capillary tube

could cause erratic operation. It cannot be straightened

without cracking its walls.

Incorrect Refrigerant Charge

An overcharged system may have a frost back condition

appearing outside the insulation sleeve on the suction

line at the rear of the cabinet. When the compressor

stops, frost melts and drips on the floor.

System must be purged, evacuated, and recharged with

the correct amount of refrigerant.

An undercharged system will operate with temperatures

above normal and compressor operating time will be

increased. The greater the undercharge, higher the

temperatures and longer the operating time.

The system must be purged, evacuated, and recharged

with the correct amount of refrigerant. Before recharging,

test for refrigerant leaks.

Partial Restriction in Low Side Tubing

Bent tubing, foreign matter, or moisture in the system,

may cause a partial restriction in the low side tubing.

This usually results in frost-free tubing between the

restriction and capillary tube and frost-covered tubing

between the restriction and suction line. This restrictions

acts like a second capillary tube, increasing pressure

behind it (warming) and decreasing pressure beyond it

(cooling). Replace component if there is a partial

restriction in the refrigerant tubing.

Pressure Unloading in System

Compressor may stall and cycle on overload if an

attempt is made to restart unit immediately after it has

stopped. Compressor is trying to start while refrigerant

pressure is high on condenser side and low on

evaporator side. When the compressor stops operating,

pressure in both sides equalizes as the liquid slowly

passes through the capillary tube. When this occurs the

pressures are said to be unloaded. Pressure unloading

in the system will usually take from 3 to 6 minutes.

Pull Down Over Load

If cabinet interior is warm when compressor starts, pull

down may overheat the compressor and cause cycling

on the overload protector.