RS1500000 Rev. 0

46

Service Information

To avoid risk of electrical shock, personal injury, or death,

always disconnect electrical power source to the freezer

before attempting to service unless test procedures require power to be connected. When removing any wiring from

terminals, replace on the same terminals. Ensure all ground wires are connected before certifying unit as repaired

and/or operational.

WARNING

!

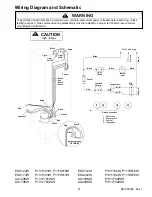

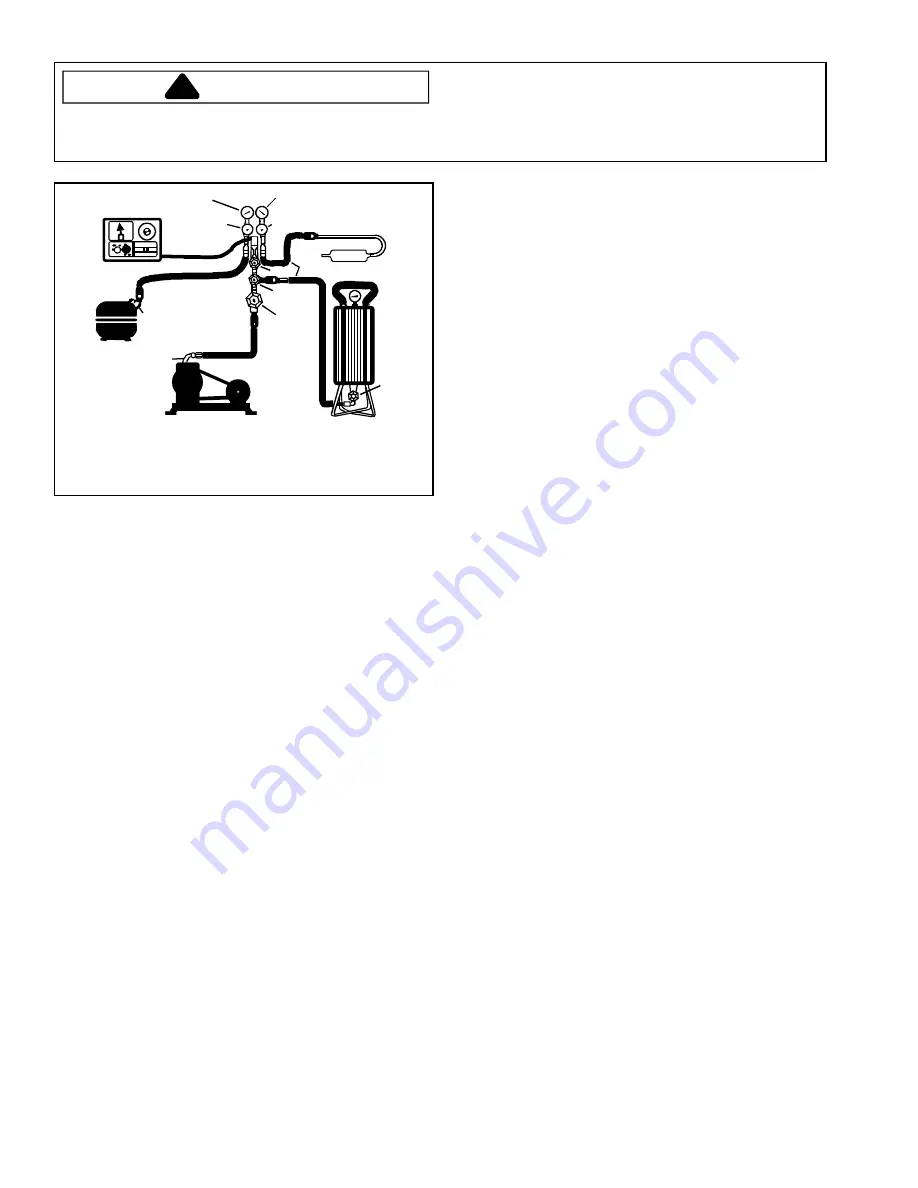

Vacuum Pump

.6 cm Copper

Tubing

Compressor

Compressor

Process

Tube

Charging Hose

Thermistor

Vacuum Gauge

Low Side Gauge

E

Valve

B

D

Valve

High Side Gauge

Charging Hose

Drier/Process Tube

F

Valve

Charging

Cylinder

C

A

Evacuation and Charging

Typical Setup

Before opening system, evaporator coil must be at

ambient temperature to minimize moisture infiltration into

system.

NOTE

: It is the responsibility of the service technician to

capture refrigerant in system for safe disposal,

before opening any refrigeration system.

1. After capturing refrigerant, replacing drier and making

any repairs, evacuate system from high side through

drier/process tube and low side through compressor

process tube simultaneously. Evacuation should not

be done through line piercing valve but through I.D.

opening of tubes.

2. With valves C and F closed to thermistor vacuum

gauge and charging cylinder, open all other valves

and start vacuum pump.

3. At approximately 77.66 cm (29") of vacuum, open

valve C to thermistor vacuum gauge and take

micron reading.

4. Continue evacuating system until thermistor vacuum

gauge registers 600 microns.

5. At 600 microns close valve A to vacuum pump to

allow micron reading in system to balance. Micron

level will rise. If in 2 minutes, micron level stabilizes at

1000 microns or below, system is ready for charging.

If micron rises above 1000 micron level and

stabilizes, open valve A to vacuum pump and

continue evacuating.

If micron reading rises rapidly and does not

stabilize, a leak still exists in system. Close valve

A to vacuum pump and C to thermistor vacuum

gauge. Invert charging cylinder and open charging

cylinder valve F to add partial charge for leak

checking. With leak detector, check manifold

connections and system for leaks. After locating

leak, capture refrigerant charge, repair leak, and

begin at step 1.

6. Once system is ready to charge, close valve A

(vacuum pump), C (thermistor vacuum gauge), and

E (low side manifold gauge).

7. Check serial plate for correct charge and set scale on

dial-a-charge cylinder for corresponding HFC134a

pressure reading.

NOTE

: Do not use captured or recycled refrigerant in

Amana units. Captured or recycled refrigerant

voids any Amana and/or compressor

manufacture's warranty.

8. Open valve F to charging cylinder and let exact

amount of refrigerant out of cylinder. Close valve.

Low side gauge pressure should rise shortly after

opening charging cylinder valve as system pressure

equalizes through capillary tube. If pressure does not

equalize, a restriction typically exists at capillary/drier

braze joint.

9. If no restriction exists, open valve E (low side

manifold gauge) and pinch off high side drier process

tube.

10.Start compressor and draw remaining refrigerant in

charging hoses and manifold into compressor

through compressor process tube. To check high

side pinch-off drier process tube, close valve D

(high side gauge). If pinch-off is not leaking, high side

pressure will not rise. If high side pressure gauge

shows an increase, repeat high side pinch-off and

open valve D. Repeat until high side pinch-off no

longer leaks.

11. Pinch-off compressor process tube and remove

charging hose. Braze stub closed while compressor

is operating.

12.Unplug dehumidifier from electrical outlet. Remove

charging hose and braze high side drier process tube

closed.