RS1500000 Rev. 0

30

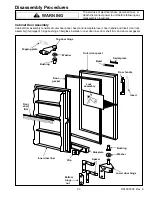

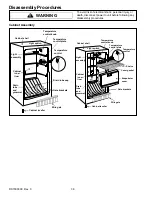

Disassembly Procedures

To avoid risk of electrical shock, personal injury, or

death, disconnect power to unit before following any

disassembly procedures.

WARNING

!

18.Secure control feeler tube to correct shelf with the

clamp. Verify feeler tube rests firmly against shelf

surface to obtain thermal contact.

19.Form heat exchanger tubing so it is similar in position

to the original. Be careful when bending tubing at the

entry hole to prevent kinks.

20.Pack tube entry hole with butyl sealer.

21.If cut when remove, swedge compressor suction

tubing to fit replacement tubing

22.Install new drier and connect all tubing. Silver solder

the joints with proper flux. Excess flux must be wiped

off tubing after soldering.

23.Visually check all joints for leaks. Evacuate and

recharge the system.

24.Test run the unit to verify proper operation.

25.Pinch process tube and cut off the service valve.

Solder the joint and test for leaks.

Replacing Freezer Coil No-Defrosting

Models

Because of freezer coil location, do not attempt

replacement without first removing coil and heat

exchanger from the cabinet. Even though an

experienced silver brazer can control a torch flame,

possibility of overheating and distorting plastic is high.

1. Disconnect line cord from electrical outlet.

2. Install service valve as close as possible to tip of

process tube for easy pinch-off after recharging the

system.

3. Connect a hose to service valve and capture the

charge.

NOTE:

Effective July 1, 1992, before opening any

refrigeration system it is the responsibility of the

service technician to capture the refrigerant for

safe disposal.

4. Remove butyl sealer from tube entry hole in the

cabinet back.

5. Clean approximately three inches (76 mm) of the

heat exchanger tubing at the compressor stub.

Unsolder at the joint or cut three inches (76 mm)

from the stub.

6. Unsolder drier from condenser outlet tube and clean

the outlet. Remove drier from capillary tube so tubing

assembly can be pulled through the tube entry

opening.

7. Remove screws securing freezer coil cover. Lift cover

out and detach green grounding wire.

8. Remove styrofoam air block from each end of the

coil.

9. Disconnect defrost heater lead from spade terminal

on fan motor.

White

White

Orange

Green

Red

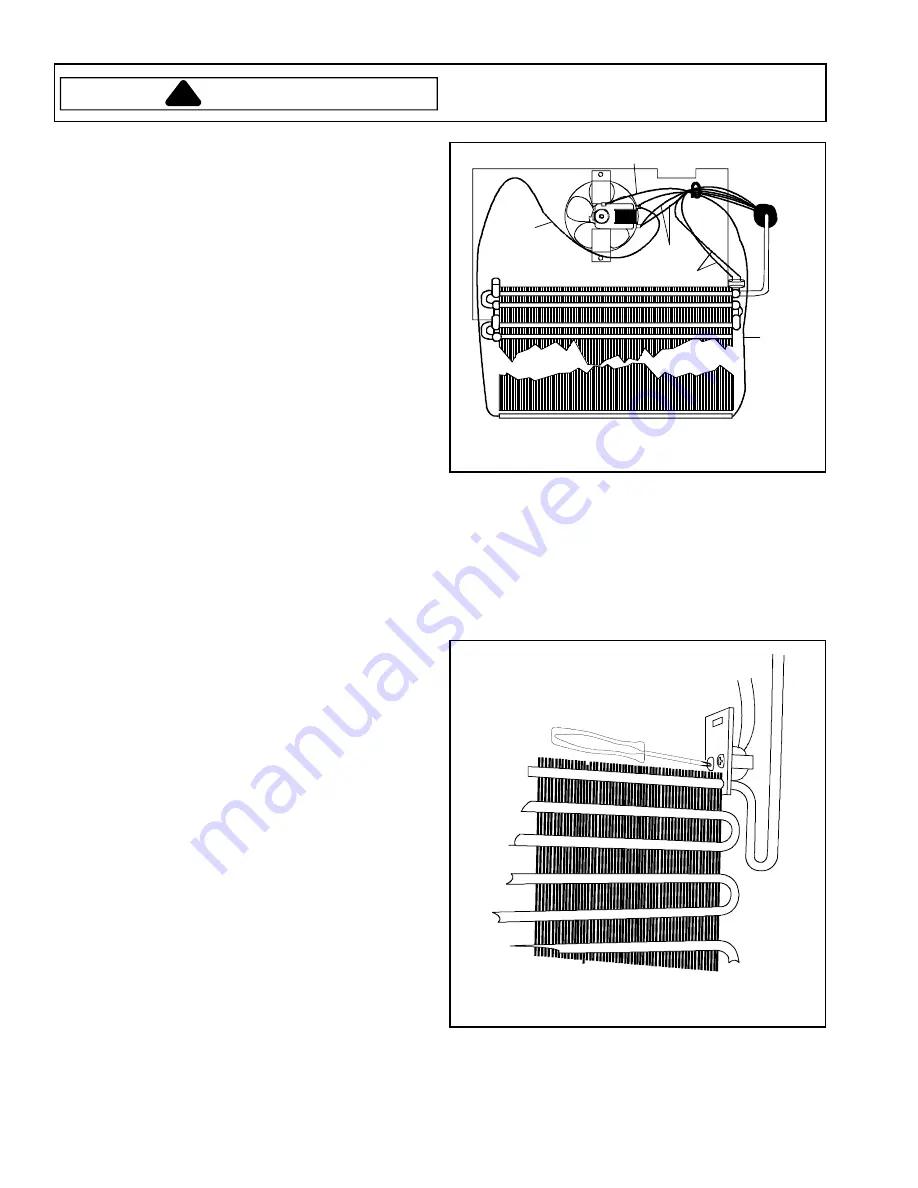

Circulating Fan and Wiring With

Coil Cover Removed

10.Spade connector is used to join the white defrost

heater lead to the white lead-in wire. Separate these

wires at the spade connector. Release heater lead

from the two clips on the coil mounting panel and

unlace it from the coil.

11. Disconnect white defrost heater lead from defrost

thermostat and unlace it from freezer coil.

12.Remove defrost thermostat from coil header to

release the front tang.

Removing Defrost Thermostat

No Defrost Models

13.Detach green grounding wire from freezer coil

header.

14.Remove screws securing freezer coil to coil mounting

panel. The coil is now free to be removed.