20

CI/AZ40-EN Rev. A

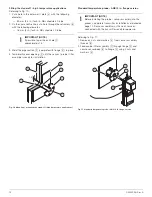

Setting up and recording pneumatic values

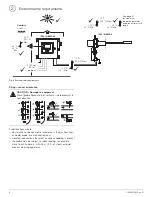

Referring to Fig. 22.

1. Perform a leak test on all pneumatic connections.

2. Attach a pressure measuring device to sensor assembly

instrument air supply tee fitting

A

. Verify that the instrument

air supply pressure is 207 ±3 kPa (30.0 ±0.5 psi) and adjust

the pressure if necessary.

3. Attach a pressure measuring device with a range of 0 to

–69 kPa (0 to –10 psig) to aspirator suction pressure port

B

. Verify that the suction pressure is –51.7 to –65.5 kPa (–

7.5 to –9.5 psig).

Record the suction pressure in Table 4.

4. Attach a pressure measuring device (inches H

2

O) to test gas

port

C

. Measure the pressure with instrument air on to

obtain the sample pressure.

Record the sample pressure in Table 4.

5. Measure the pressure at test gas port

C

with the instrument

air turned off to obtain the duct pressure. Verify that the

sample duct is –5 to 5 kPa (–20 to 20 inches H

2

O).

Turn the instrument air back on after taking this

measurement.

Record the duct pressure in Table 4.

6. Calculate the filter pressure drop by subtracting the sample

pressure from the duct pressure. Verify that the filter pressure

drop is less than 2 kPa (8 inches H

2

O).

Record the filter pressure drop in Table 4.

Fig. 22 Pneumatic value check points on AZ40 sensor

+

–

+

–

Parameter

Date

New analyzer

Pressure and flow limits

Sample pressure

____________

kPa (in. H

2

O)

_____

_____

Duct pressure

____________

kPa (in. H

2

O)

_____

±5 kPa (±20 in. H

2

O)

Filter pressure drop

(duct pressure – sample pressure)

____________

kPa (in. H

2

O)

0.5 kPa (in. H

2

O)

2 kPa (8 in. H

2

O)

Aspirator suction pressure

____________

kPa (psig)

55 to 69 kPa (8 to 10 psig)

34 to 69 kPa (5 to 10 psig)

Minimum sample gas flowrate

____________

SCFH (i/min)

3.5 to 4.5 SCFH (1.6 to 2.1 i/m)

2.5 to 4.7 SCFH (1.2 to 2.2 l/m)

Table 4 Sensor assembly pressure and flow data