5-9

CHAPTER 5 Periodic Inspection

5

Replacing the Harmonic Drive

The YK-XG series robots listed in Table 5-1 use a harmonic drive as the speed

reduction gear for the X, Y and R axes. Harmonic drives need to be replaced after

a specified operation time. Use the guideline explained below to determine the

replacement period and replace the harmonic drive periodically. Since the YK-

XG series robots listed in Table 5-1 use long-life harmonic grease, it is not neces-

sary to replace the harmonic grease.

5-1

Replacement period

The harmonic drive replacement period is determined by the total number of

turns of the wave generator used in the harmonic drive. It is recommended to

replace the harmonic drive when the total number of turns has reached 8.4

×

10

8

(at ambient operating temperatures of 0

°

C to +40

°

C). This means that the re-

placement period will differ depending on the following operating conditions. If

the robot operation duty ratio is high or the robot is operated in environments at

higher temperatures, the harmonic drive should be replaced earlier.

Replacement period = 8.4

×

10

8

/(n

×

60

×

h

×

D

×

N

×θ

) years

where

n

: Number of axis movements per minute

θ

: Average turn per axis movement

N

: Speed reduction ratio

h

: Operation time per day

D

: Operation days per year

For example, when the robot is used under the following conditions, the replacement

period for the X-axis harmonic drive of the YK500XG can be calculated as follows.

n

: 10

θ

: 0.25

N

: 80

h

: 24 hours per day

D

: 240 days per year

Replacement period = 8.4

×

10

8

/(n

×

60

×

h

×

D

×

N

×θ

)

= 8.4

×

10

8

/(10

×

60

×

24

×

240

×

80

×

0.25)

= 12.2 years

Robot model

YK500XG, YK600XG

YK600XGH, YK700XG, YK800XG, YK900XG, YK1000XG

80

80

80

80

30

50

X-axis

Y-axis

R-axis

Table 5-1 Harmonic drive speed reduction ratio

Table 5-2 Bolt tightening torque

Bolt size

Tightening torque (kgfcm)

Tightening torque (Nm)

M3 button head bolt

14

20

1.4

M3

20

2.0

M4

46

4.5

M5

92

9.0

M6

156

15.3

M8

380

37

M10

720

71

M4 set screw

2.0

Recommended "Screw Lock": LOCTITE 262 (made by Henkel Corporation)

Use only YAMAHA genuine bolts or JIS B 1176 hex socket head bolts

(strength class: JIS B 1051 12.9).

Summary of Contents for YK-X Series

Page 1: ...User s Manual ENGLISH E YAMAHA SCARA ROBOT E35 Ver 1 08 YK XG YK X series ...

Page 2: ......

Page 6: ...MEMO ...

Page 10: ...MEMO ...

Page 12: ...MEMO ...

Page 30: ...MEMO ...

Page 36: ...MEMO ...

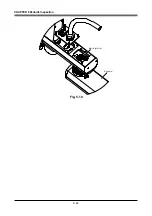

Page 46: ...3 10 CHAPTER 3 Installation Ground symbol M4 Ground terminal Fig 3 6 Ground terminal ...

Page 78: ...3 42 MEMO ...

Page 80: ...MEMO ...

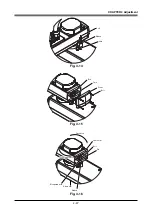

Page 101: ...4 21 CHAPTER 4 Adjustment Cover Elongated hole Y axis origin sensor stay Bolt Fig 4 8 a ...

Page 102: ...4 22 CHAPTER 4 Adjustment Dog Hex nut Fig 4 8 b Bolt Y axis arm X axis arm Fig 4 8 c ...

Page 119: ...4 39 CHAPTER 4 Adjustment R End effector End effector Z Y X Fig 4 18 ...

Page 120: ...4 40 MEMO ...

Page 122: ...MEMO ...

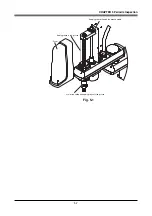

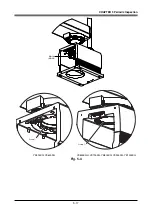

Page 138: ...5 16 CHAPTER 5 Periodic Inspection M6 16 M5 16 X axis motor Base Fig 5 3 ...

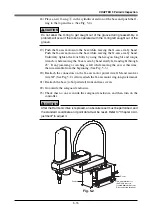

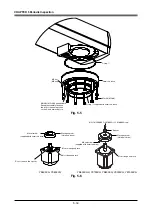

Page 146: ...5 24 CHAPTER 5 Periodic Inspection M3 16 M4 18 X axis arm Fig 5 10 ...

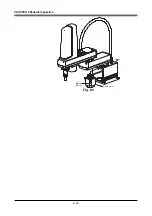

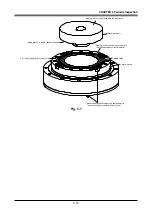

Page 155: ...5 33 CHAPTER 5 Periodic Inspection O ring r M5 14 M6 16 R axis motor Fig 5 17 ...

Page 156: ...5 34 CHAPTER 5 Periodic Inspection M3 14 M3 16 O ring w Fig 5 18 ...

Page 161: ...CHAPTER 6 Increasing the robot operating speed 1 Increasing the robot operating speed 6 1 ...

Page 162: ...MEMO ...

Page 168: ...6 6 MEMO ...

Page 170: ...MEMO ...

Page 177: ...MEMO ...