5 - 82

ENG

CRANKCASE AND CRANKSHAFT

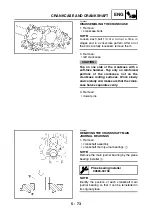

5. Install:

• balancer connecting rod

• connecting rod cap

CAUTION:

• When tightening the nuts be sure to use

an F-type torque wrench.

• Without pausing, tighten to full torque

specification. Apply continuous torque

57 ~ 63 Nm (5.7 ~ 6.3 m · kg, 41 ~ 45 ft · lb).

Once you reach 57 Nm (5.7 m · kg, 41 ft · lb)

DO NOT STOP TIGHTENING until final

torque is reached. If the tightening is inter-

rupted 57 ~ 63 Nm (5.7 ~ 6.3 m · kg, 41 ~

45 ft · lb) loosen the nut to less than 57 Nm

(5.7 m · kg, 41 ft · lb) and start again.

T

R

.

.

60 Nm (6.0 m · kg, 43 ft · lb)

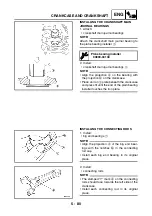

INSTALLING THE CRANKSHAFT

1. Install:

• crankshaft assembly

1

• balancer piston cylinder

2

CAUTION:

To avoid scratching the crankshaft and to

ease the installation procedure, apply

grease onto the oil seal lips and apply

engine oil onto each bearing.

T

R

.

.

58 Nm (5.8 m · kg, 42 ft · lb)

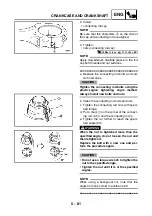

EAS00418

ASSEMBLING THE CRANKCASE

1. Thoroughly clean all the gasket mating sur-

faces and crankcase mating surfaces.

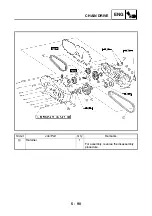

Summary of Contents for XP500

Page 1: ...2005 XP500 XP500A5VU5 AE1 SERVICE MANUAL...

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1...

Page 11: ...GEN INFO...

Page 38: ...SPEC 2...

Page 40: ...SPEC...

Page 68: ...2 28 SPEC OIL FLOW DIAGRAMS 1 Oil strainer 2 Crankshaft...

Page 69: ...2 29 SPEC OIL FLOW DIAGRAMS 1 Clutch 2 Right main journal bearing 3 Main gallery plug...

Page 118: ......

Page 119: ...CHK ADJ 3...

Page 193: ......

Page 194: ...CHAS 4...

Page 198: ...CHAS...

Page 292: ...4 94 CHAS ANTI LOCK BRAKE SYSTEM XP500A...

Page 326: ......

Page 327: ...ENG 5...

Page 331: ...ENG...

Page 424: ...COOL 6...

Page 426: ...COOL...

Page 442: ......

Page 443: ...FI 7...

Page 445: ...FI...

Page 476: ...ELEC 8...

Page 544: ......

Page 545: ...TRBL SHTG 9...

Page 553: ......

Page 556: ......

Page 557: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN...