17

Special safety instructions

p)

Do not use any attachments that require

liquid coolants.

The use of water or other

liquid coolants can lead to an electric shock.

Recoil and corresponding safety

instructions

Recoil is the sudden reaction due to a rotating

attachment (e.g. grinding wheel, grinding disc,

wire brush, etc.) snagging or blocking, Snagging

or blocking results in a sudden stoppage of the

rotating attachment. This causes an uncontrolled

electric tool to accelerate in the opposite direction

to the direction of rotation of the attachment at the

blocking point. If, for example, a grinding wheel

snags or blocks in the workpiece, that edge of the

grinding wheel entering the workpiece may snag

and cause the grinding wheel to break out or to

cause a recoil. The grinding wheel then moves

towards or away from the operator, depending on

the direction of rotation of the wheel at the blocking

point. This can also cause grinding wheels to break.

A recoil is the result of incorrect or improper use of

the electric tool. It can be avoided by taking appro-

priate precautions as described below.

a)

Hold the electric tool firmly and bring

your body and arms into a position in

which you can absorb the recoil forces.

Always use the auxiliary handle, if

fitted, in order to have the greatest

possible control over recoil forces or

reaction moments during starting.

By

taking appropriate precautions, the operator can

control the recoil and reaction forces.

b)

Never put your hands near a rotating

attachment.

The attachment can travel over

your hand in the event of a recoil.

c)

Keep your body out of the area in which

the electric tool will move in the event of

a recoil.

The recoil drives the electric tool in the

opposite direction to the movement of the grind-

ing wheel at the blocking point.

d)

Work particularly carefully in the vicin-

ity of corners and sharp edges, etc.

Prevent attachments from rebounding

from the workpiece and jamming.

The

rotating attachment tends to jam at corners or

sharp edges or if it rebounds from the workpiece.

This causes a loss of control or recoil.

e)

Do not use a chain saw blade or saw

blade with teeth.

Such attachments frequently

cause a recoil or the loss of control over the

electric tool.

Special safety precautions for grind-

ing and abrasive cut-off operations:

f)

Use only grinding wheels that are

approved for your electric tool and the

safety hoods intended for these grinding

wheels. Grinding wheels that are not

approved for the electric tool cannot be

adequately shielded and are unsafe.

g)

Offset grinding wheels must be at

-

tached so that the grinding surface is

located beneath the safety guard.

An

incorrectly attached grinding wheel protruding

beyond the edge of the safety hood cannot be

shielded adequately.

h)

The safety hood must be securely fitted

to the electric tool and adjusted for max-

imum security so that only the smallest

possible part of the grinding wheel is

open and facing towards the operator.

The safety hood helps to protect the operators

from broken pieces, from accidental contact with

the grinding wheel and from sparks that could

cause clothing to ignite.

i)

Grinding wheels may only be used for

the recommended applications.

E.g.:

never grind with the side surface of a grinding

wheel. Grinding wheels are intended for material

removal with the end of the wheel. Forces acting

on the side of these grinding wheels can cause

them to break.

j)

Always use undamaged clamping

flanges with the right size and form for

the grinding wheel used.

Suitable flanges

support the grinding wheel and thus reduce the

danger of a grinding wheel breakage. Flanges

for cut-off grinding wheels can differ from the

flanges for other grinding wheels.

k)

Do not use worn grinding wheels from

larger electric tools.

Grinding wheels for

larger electric tools are not designed for the

higher speeds of smaller electric tools and can

break.

Further special safety precautions for

cut-off wheels:

a)

Avoid blocking of the cut-off wheel or

excessive contact pressure.

Do not make

excessively deep cuts. Overloading of the cut-off

wheel increases the pressure and the susceptibil-

ity to tilting or blocking, and hence the risk of a

recoil or grinding wheel breakage.

Summary of Contents for FKWS 9-125

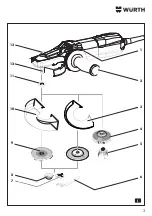

Page 3: ...3 I 12 13 6 2 1 4 3 7 9 8 10 11 5...

Page 4: ...12 B A C 4 III II 14 3...

Page 111: ...111 GR Adolf W rth GmbH Co KG 3 1...

Page 112: ...112 a b c d e f g...

Page 113: ...113 h i j k l m n o p a...

Page 114: ...114 b c d e f g h i j k a b...

Page 115: ...115 c d e f a a b...

Page 116: ...116 FI FI P2 FI 30 mA...

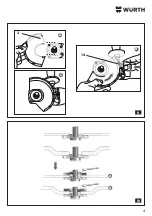

Page 118: ...118 I II 1 2 3 4 5 6 7 8 9 10 11 12 13 14 2 II 3 4 mm 14 3 3 13...

Page 119: ...119 8 9 6 mm 7 6 8 8 12 8 8 8 6 III 11 3 9 11 III 7 7 7 7 6 7 6...

Page 120: ...120 1 1 30 40 W rth...

Page 193: ...193 BG Adolf W rth GmbH Co KG 3 1...

Page 194: ...194 a b c d e f g...

Page 195: ...195 h i j k l m n o p...

Page 196: ...196 a b c d e f g h i j a b...

Page 197: ...197 c d e f a a b...

Page 198: ...198 FI FI P2 30 mA...

Page 200: ...200 1 2 3 4 5 6 7 8 9 10 11 12 13 14 2 3 4 mm 14 3 3 13...

Page 201: ...201 8 9 6 mm 7 6 8 8 12 8 8 8 6 11 3 9 11 7 7 7 7 6 7 6...

Page 202: ...202 1 1 30 40 W rth...

Page 234: ...234 RU Adolf W rth GmbH Co KG 3 1...

Page 235: ...235 a b c d e f g...

Page 236: ...236 h i j k l m n o p a...

Page 237: ...237 b c d e f g h i j k a b c...

Page 238: ...238 d e f a a b...

Page 239: ...239 FI P2 30 A...

Page 241: ...241 I II 1 2 3 4 5 6 7 8 9 10 11 12 13 14 2 II 3 4 14 3 3...

Page 242: ...242 III 7 7 7 7 6 7 6 8 9 6 7 6 8 13 III 11 3 9 11...

Page 243: ...243 8 12 8 8 8 6 1 1 30 40...

Page 244: ...244 W rth 1 W rth masterService http www wuerth com partsmanager W rth...