16

Special safety instructions

Safety Warnings Common for Grind-

ing, Sanding, Wire Brushing, and

Abrasive Cutting-Off Operations:

Application

a)

This electric tool is to be used as a

grinder, sander, wire brush and cut-off

grinder. Observe all the safety instruc-

tions, precautions, illustrations and data

supplied with the device.

Failure to observe

the following instructions can result in electric

shock, fire and/or serious injuries.

b)

This electric tool is not suitable for

polishing.

Uses for which the electric tool is not

intended may result in dangers and injuries.

c)

Do not use any accessories not specifi

-

cally intended or recommended for this

electric tool.

Just because the accessory can

be fitted to your electric tool does not mean that

it can be used safely.

d)

The permissible speed of the accessory

used must be at least as high as the

maximum speed indicated on the electric

tool.

Accessories that run faster than permitted

can burst and parts may fly around.

e)

Outside diameter and thickness of

the accessory used must conform to

the specifications of your electric tool.

Incorrectly dimensioned attachments cannot be

adequately shielded or controlled.

f)

Accessories with inserted thread must fit

exactly onto the grinding spindle of the

electric tool. With accessories attached

using a flange, the form of the flange

must fit exactly to the mounting boring.

At-

tachments that do not fit exactly onto the mounting

fixture of the electric tool rotate erratically, vibrate

very strongly and may lead to a loss of control.

g)

Do not use damaged accessories.

Before every use, inspect accessories

such as grinding wheels for splintering

and cracks, grinding discs for cracks or

severe wear and wire brushes for loose

or broken wires. If the electric tool or

accessory falls down, check whether

it is damaged or use an undamaged

accessory. When you have inspected

and fitted the accessory, keep yourself

and other persons in the vicinity outside

the plane of the rotating accessory and

allow the device to run at maximum

speed for one minute.

Damaged attachments

normally break during this test time.

h)

Wear personal protective equipment.

Depending on the application, use a full

face mask, eyeshield or protective gog-

gles. If appropriate, wear a dust mask,

hearing protection, protective gloves or

a special apron that protects you from

small grinding and material particles.

The eyes should be protected from flying foreign

matter that can occur during various applications.

The dust mask or face mask must be suitable for

filtering out the dust created during the applica

-

tion. If you are exposed to a loud noise for a pro-

longed period, you may suffer a loss of hearing.

i)

Ensure that other persons stay a safe

distance away from your working area.

Everyone entering the working area

must wear personal protective equip-

ment.

Broken pieces of the workpiece or broken

attachments can fly off and cause injuries even

outside the direct working area.

j)

Hold the device only at the insulated

handles when carrying out work where

the attachment could contact concealed

electricity cables or the mains lead of

the electric tool.

Contact with a live cable can

make metallic parts of the device live and may

lead to an electric shock.

k)

Keep the mains lead away from rotat-

ing attachments.

If you lose control over the device, the mains lead

may be severed or caught up and may pull your

hand or arm into the rotating attachment.

l)

Never put the electric tool down before

the attachment has come to a complete

standstill.

The rotating attachment may make

contact with the surface on which it is placed and

could cause you to lose control of the electric

tool.

m)

Do not allow the electric tool to run

while you are carrying it.

Your clothing

could come into contact with the rotating attach-

ment and cause the attachment to bore into your

body.

n)

Clean the ventilation slots of your elec-

tric tool at regular intervals.

The motor fan

draws dust into the housing, and a heavy accu-

mulation of metal dust may pose electric hazards.

o)

Do not use the electrical tool in the vicin-

ity of flammable materials.

Sparks could

cause these materials to ignite.

Summary of Contents for FKWS 9-125

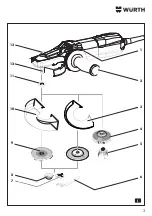

Page 3: ...3 I 12 13 6 2 1 4 3 7 9 8 10 11 5...

Page 4: ...12 B A C 4 III II 14 3...

Page 111: ...111 GR Adolf W rth GmbH Co KG 3 1...

Page 112: ...112 a b c d e f g...

Page 113: ...113 h i j k l m n o p a...

Page 114: ...114 b c d e f g h i j k a b...

Page 115: ...115 c d e f a a b...

Page 116: ...116 FI FI P2 FI 30 mA...

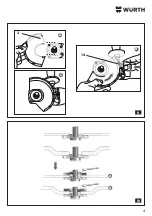

Page 118: ...118 I II 1 2 3 4 5 6 7 8 9 10 11 12 13 14 2 II 3 4 mm 14 3 3 13...

Page 119: ...119 8 9 6 mm 7 6 8 8 12 8 8 8 6 III 11 3 9 11 III 7 7 7 7 6 7 6...

Page 120: ...120 1 1 30 40 W rth...

Page 193: ...193 BG Adolf W rth GmbH Co KG 3 1...

Page 194: ...194 a b c d e f g...

Page 195: ...195 h i j k l m n o p...

Page 196: ...196 a b c d e f g h i j a b...

Page 197: ...197 c d e f a a b...

Page 198: ...198 FI FI P2 30 mA...

Page 200: ...200 1 2 3 4 5 6 7 8 9 10 11 12 13 14 2 3 4 mm 14 3 3 13...

Page 201: ...201 8 9 6 mm 7 6 8 8 12 8 8 8 6 11 3 9 11 7 7 7 7 6 7 6...

Page 202: ...202 1 1 30 40 W rth...

Page 234: ...234 RU Adolf W rth GmbH Co KG 3 1...

Page 235: ...235 a b c d e f g...

Page 236: ...236 h i j k l m n o p a...

Page 237: ...237 b c d e f g h i j k a b c...

Page 238: ...238 d e f a a b...

Page 239: ...239 FI P2 30 A...

Page 241: ...241 I II 1 2 3 4 5 6 7 8 9 10 11 12 13 14 2 II 3 4 14 3 3...

Page 242: ...242 III 7 7 7 7 6 7 6 8 9 6 7 6 8 13 III 11 3 9 11...

Page 243: ...243 8 12 8 8 8 6 1 1 30 40...

Page 244: ...244 W rth 1 W rth masterService http www wuerth com partsmanager W rth...