Sawmill Alignment

Saw Head Slide Pad Adjustment

Sawmill Alignment

doc012020

5-4

5

Be sure to tighten all nuts against the mounting plates when the adjustment is complete.

The vertical angle of the drive side wheel is factory-set and should not need to be adjusted. If

adjustment is needed use the vertical adjustment bolts. To tilt the wheel upward, tighten the top bolt

and loosen the bottom bolt. To tilt the wheel downward, tighten the bottom bolt and loosen the top

bolt.

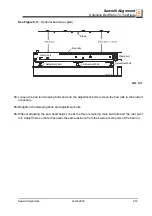

5.4

Saw Head Slide Pad Adjustment

There are eight nylon pads positioned between the saw head frame and vertical mast. The spacing

of the pads is factory set and rarely needs adjusting. To check the pad spacing, perform the following

steps.

NOTE:

The pads on the engine side of the mast are referred to as the "inner" pads. The pads on the

control side of the mast are referred to as the "outer" pads.

NOTE:

Shims are often used around the clamping bolts, between the C-frame support bracket and

the mast v-brace. The shims align the v-brace to the mast so that the entire face of each slide pad

makes contact with the mast. Be sure to keep these shims in place when performing the following

adjustment.

FIG. 5-3

AC0032

Horizontal

Adjustment Nuts

Vertical

Adjustment Bolt