13

November 2008

Part No. 920559 Rev H

2.7 Hose and Hose Retractor

Hose assemblies should be U.L. Listed and installed in accordance with the manufacturer’s instructions. To

ensure a proper joint, wash all cutting oil off the threads and use a U.L. classified gasoline-resistant pipe joint

sealing compound. Place the compound on male threads only; be careful not to get any excess compound

inside fittings. Install the fixed end of the hose to the dispenser outlet; secure according to the instructions of

the sealing compound and hose manufacturers. Install the swivel end of the hose or other swivels to the noz-

zle according to the manufacturer’s instructions.

Exception:

Do not use the sealant on balanced or inverted hoses used with vapor recovery.

NFPA code requires a Listed emergency breakaway device, designed to retain liquid on both sides of the

breakaway point, must be installed on each hose dispensing Class I liquids; these devices must be installed

and maintained per the manufacturer’s instructions. Refer to your state and local codes for breakaway device

requirements that apply to your installation.

On E85 Ovation dispensers, all hoses, nozzles, breakaways, etc., containing the Ethanol fuel must be Ethanol

compatible. See the information in Section 1.1 on page 1.

On Wayne vapor recovery dispensers all hoses, nozzles, and breakaways, etc., must be CARB certified.

Hose Retractor

: Caution!:

On dispensers equipped with the Hose Retractor option, the hose clamp must

be mounted upstream of the breakaway device to avoid damage to the dispenser in the event of a drive-off.

The combined hose, breakaway, and whip maximum lengths are listed below.

WARNING

Use only Listed hoses and nozzles. Continuity must be present between the dispenser outlet and nozzle

spout to prevent static discharge while fueling. Continuity must be checked for each outlet/hose assem-

bly to insure that the nozzle is grounded. Failure to do so may result in a hazardous condition that could

cause serious injury.

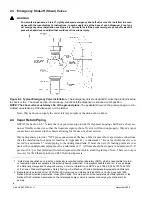

2.8 Bleeding Product Lines (Remote Dispensers)

NOTE:

To avoid severe damage to the dispenser, all air and air pockets must be bled from the product trunk

lines before attempting to dispense product.

Step 1

Make sure the power to the appropriate submersible pump is OFF.

Step 2

To bleed air from a trunk line, remove the pipe plug from the safety impact valve on the dispenser

farthest from the storage tank. For pipe plug location see Figure 2-2 earlier in this section.

Step 3

Attach a flexible hose to the pipe plug opening in the safety impact valve. Energize the appropriate

submersible pump and allow the air to bleed out of the trunk line into a test can until product flows

into the test can. De-energize the submersible pump and replace the pipe plug. Repeat the procedure

for each product and each trunk line.

Crossover Type

1 Hose per Side

Loopback Type

1 Hose per Side

Loopback Type

2 Hose per Side

Wayne Vac

14’ 0’’

Non-Vapor 3/4”

10’ 0’’

10’ 0’’

Non-Vapor 5/8”

14’ 0’’

14’ 0’’

Summary of Contents for Ovation

Page 1: ...INSTALLATION Ovation Dispensers OPERATION...

Page 3: ...November 2008 Part No 920559 Rev H Ovation Series Dispensers Installation Operation...

Page 4: ...November 2008 Part No 920559 Rev H...

Page 54: ...48 Part No 920559 Rev H November 2008...

Page 66: ...60 Part No 920559 Rev H November 2008...

Page 67: ...61 November 2008 Part No 920559 Rev H DISTANCE BETWEEN EYE BOLTS 33 1...

Page 68: ...62 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL R13...

Page 69: ...63 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL R13...

Page 70: ...64 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL B23...

Page 71: ...65 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL B23...

Page 74: ...68 Part No 920559 Rev H November 2008 INSTALLATION INSTRUCTION page 1 of 2 OVATION MODEL R11...

Page 75: ...69 November 2008 Part No 920559 Rev H INSTALLATION INSTRUCTION page 2 of 2 OVATION MODEL R11...

Page 76: ...70 November 2008 Part No 920559 Rev H...

Page 77: ...71 November 2008 Part No 920559 Rev H 2 7151 C TYPICAL SITE WIRING...

Page 78: ...72 Part No 920559 Rev H November 2008...

Page 80: ...74 Part No 920559 Rev H November 2008...

Page 81: ...75 November 2008 Part No 920559 Rev H APPENDIX D SITE INTERCONNECTION DIAGRAMS...

Page 82: ...76 Part No 920559 Rev H November 2008 Figure D 1 Backroom Installation Wayne Control System...

Page 84: ...78 Part No 920559 Rev H November 2008 Figure D 3 Pump Relay Installation Wiring Diagram...